TM-5-3805-254-14-P-2 - Page 257 of 894

ELECTRICAL

TRUCK SERVICE MANUAL

1.

Do not polarize the integral charging system.

2.

Do not short across or ground any of the terminals in

the charging circuit except as specifically instructed

herein.

3.

Make sure the integral charging system and battery

have the same ground polarity.

4.

When connecting a charger or a booster battery to

the vehicle battery, connect negative

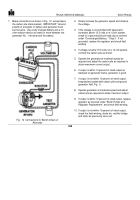

Fig.

3

Trouble in the charging system will show up as one

or more of the following conditions:

A. An undercharged battery or energizer, as evidenced

by slow cranking and low specific gravity readings.

B. An overcharged battery or energizer, as evidenced

by excessive water usage.

A. Undercharged Battery

This condition, as evidenced by slow cranking

and low specific gravity readings, can be caused

by one or more of the following conditions:

1.

Insure that the undercharged condition has not

been caused by accessories having been left on

for extended periods.

2.

Check the drive belt for proper tension.

3.

Inspect the wiring for defects.

Check all

connections for tightness and cleanliness,

including the cable clamps and battery posts.

4.

With ignition switch on and all wiring harness

leads connected, connect a volt-meter from:

a.

generator "BAT" terminal to ground.

b.

generator No.

1 terminal to ground.

c.

generator No.

2 terminal to ground.

A zero reading indicates an open between

voltmeter connection and battery or energizer.

NOTE :An open No.

2 lead circuit on early

production generators caused uncontrolled

voltage, battery overcharge and possible

damage to battery and accessories.

Generators

supplied for later applications have a built-in

feature which avoids overcharge and accessory

damage by preventing the generator from

turning on if there is an open in the wiring

harness connected to the No.

2 generator

terminal.

Opens in the wiring harness connected

between the No.

2 generator terminal and

battery may be between the terminals, at the

crimp between the harness wire and terminal, or

in the wire.

5.

If previous steps 1 through 4 check satisfactorily,

check integral charging system as follows:

a.

Disconnect battery ground cable.

b.

Connect an ammeter in the circuit at the

"BAT"’ terminal of the alternator.

c.

Reconnect battery ground cable.

d.

Turn on accessories.

Connect a carbon

pile across the battery.

e.

Operate engine at moderate speed as

required, usually 4000 generator RPM or

more, and adjust carbon pile as required to

obtain maximum current output.

253

Back to Top