TM-5-3805-254-14-P-2 - Page 532 of 894

TRUCK SERVICE MANUAL

6.

If flow value cannot be obtained and held, check idle

plunger (button) and governor break.

The difference

between plungers is about 5 to 10 psi.

Be certain

adapter, Part No.

144676, is used with plungers code

170 and over.

Inspect pulsation damper diaphragm.

7.

Open fuel pressure gauge valve.

With throttle in full

fuel position, increase pump speed until point at which

fuel pressure just begins to decrease (peak point).

This

should occur at speed indicated by "Governor Cut-Off

RPM".

For example’ 2130/2150 rpm on 2100 rpm pump.

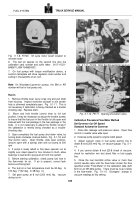

Fig.

5-1-16.

8.

If speed is lower than specified, add shims between

governor spring and retainer.

Check Table 5-1-2 for

spring specifications.

To reduce speed, remove shims.

Each 0.001 inch shim thickness will change speed

approximately 2 rpm on NH Engines.

Fig.

5-1-17,

Shims are available in 0.005, 0.007, 0.010 and 0.020

inch [0.13, 0.18, 0.25 and 0.51 mm] .

Note

: When pump is opened to make adjustments, open

main control valve to flow-meter wide open and move

throttle lever back and forth until flow-meter shows no

air, so air may be expelled more rapidly from system.

After air is expelled, reset flow-meter flow as outlined in

"Set Pump Flow."

Back to Top