TM-5-5420-203-14 - Page 26 of 298

TM 5-5420-203-14

1-7. LOCATION AND DESCRIPTION OF MAJOR COMPONENTS.

NOTE

The MLC 70 upgraded bridge folds at the center sections only. The flexible hydraulic lines

between ramp sections and center section have been replaced with hard hydraulic piping.

a. AVLB Hydraulic System.

The bridge hydraulic system consists of all the components and

mechanics required to extend and retrieve the bridge (see FIGURE 1-4). The lines, cylinders and

connectors each play a role in the operation of the bridge. The bridge needs 3800 pounds per square

inch (PSI) minimum pressure to operate. The hydraulic pump used to generate the pressure is in the

launcher. It is driven by the engine through a power take-off and a manual clutch. The control valve

bank directs the pressure to the cap or rod end of the actuating cylinder. The fluid is supplied to the

bridge by connecting lines and hydraulic cables. These lines and cables are attached to the lines of the

bridge by quick-disconnect connectors. The bridge disconnects itself when launched which reduces the

exposure of the soldier to enemy fire. The bridge uses FRH type hydraulic fluid. A hydraulic filter is

located in the system to remove any impurities that might pollute the system and cause the hydraulics to

fail.

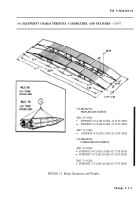

b. AVLB Structural System.

The structural system is made up of the sections, braces, supports,

curbing, and connecting hardware (see FIGURE 1-5). The bridge is made of aluminum with steel rivets

and bolts used to secure the components. The scissoring action of the bridge is a result of the extension

or retraction of the scissor cylinder. The piston of the scissor cylinder retracts which, in effect, shortens

the length of the actuating arm and cables. This results in the extension of the bridge. The reverse of

this process allows the bridge to fold under the weight of gravity when it is being held in the upright

position. The forces exerted on the scissoring components of the bridge deteriorate the moving

components. Frequent checks must be made to make sure the bridge is sound. These checks are

addressed in Preventive Maintenance Checks and Services (PMCS) in Chapter 2.

NOTE

The following features readily identify the (MLC 70) AVLB. Refer to Figure 1-5.

z

Male and female sections stenciled with 70 enclosed in circle

z

Two weight limit signs stenciled with 70 are mounted on far and near rear transverse braces

z

Lower pins, securing ramp to center section, replaced by support beam

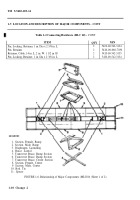

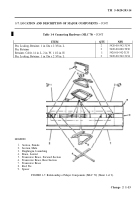

c. AVLB Major Components.

See FIGURE 1-5 for location of bridge components. FIGURE 1-5

also shows the bridge in launched position. Table 1-1 lists the item, quantity, NSN, and item number of

the bridge components, Item numbers listed on Table 1-1 correspond to items shown in FIGURE 1-6.

1-6 Change 2

Back to Top