TM-5-5420-203-14 - Page 55 of 298

TM 5-5420-203-14

NOTES:

* If the leading edge of the main angle is damaged by a gouge or nick, do not try to smooth

the rough places out by filing the area against the grain of the metal, e.g., filing 90

o

to the flange of the

angle.

This will only cause stress risers which will result in a cracked or broken main angle when placed

under the load of tanks.

** A crack of any length or width which exists in a primary structural member, e.g., hinge,

main angle, connector, splice bar, splice doubler angle, splice plate, web girder plate, quadrant, launching

diaphragm, or the cable and cylinder beams, is considered a serious condition which warrants the

immediate “deadlining” of the end item (bridge) until the item is repaired or replaced.

Until then the

bridge should be carried an NMC.

***

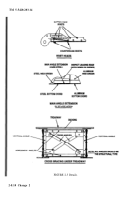

Cracks of a less serious nature are those found in secondary members, namely the

angular and plate members of cross-bracing located both underneath the treadways and the transverse and

lateral braces located between the treadways. If small cracks (1-2 inches long) are found in a secondary

member, such as cross bracing, they are considered minor but should be monitored for further

propagation.

A bridge with minor cracks in secondary members should only be “deadlined” if any of the

following conditions apply:

1) Cracks propagate through the two adjoining rivets holes in either the top

or bottom of the two vertical angle members of the cross bracing; 2) Cracks propagate eight inches in

either of the two vertical angle members starting from either the top or bottom of the angle; or 3)

Cracks propagate completely through either of the two pieces of angle that make up the cross bracing

Change 2 2-8.7

Back to Top