TM-5-5420-228-24 - Page 139 of 750

First Technician (Operator's Station)

•

Shut engine off.

•

Move ball valve to “TRAVEL” position.

•

Cycle bridge launching control levers.

Second Technician (Top Deck)

•

If STE/ICE is available, proceed to test No. 51

(page 2-58.1) to test scissors dual

counterbalance valve T1 quick disconnect

fitting.

•

If STE/ICE is not available, connect adapter

hose to gage and adapter to scissors dual

counterbalance valve T1 quick disconnect

fitting.

First Technician (Operator's Station)

•

Start engine.

•

Move ball valve to “LAUNCH” position.

•

Set engine speed at 1800 rpm.

•

Raise scissors cylinder control lever.

Second Technician (Overhead Cylinder)

•

Check if pressure gage or STE/ICE is between

3350 to 3450 psi.

Check scissors dual counterbalance valve for

pressure setting of between 3350 to 3450 psi.

13

•

Replace cartridge (C1) in

scissors dual counterbalance

valve (page 3-204.64).

•

Replace scissors dual

counterbalance valve (page 3-

204.32).

14

15

Symptom-3.1

2-80.8

Change 3

TM 5-5420-228-24

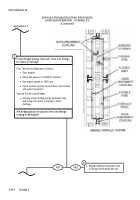

DETAILED TROUBLESHOOTING PROCEDURE

LAUNCHER OPERATION – HYDRAULICS

(Continued)

NO

YES

Always connect transducer or gage to

adapter hose before connecting to test

quick disconnect. System pressure is

released into hose at time of connection.

The hydraulic fluid can be hot and harm

your eyes, nose and ears, along with

making a mess.

WARNING

Is pressure between 3350 to 3450 psi?

TEST PORT

T2

TEST PORT

T1

Back to Top