TM-55-2350-262-14 - Page 30 of 42

TM55-2350-262-14

CHAPTER 6

MARINE AND TERMINAL TRANSPORTABILITY GUIDANCE

Section I.

6-1. Scope

This chapter provides marine and terminal trans-

portability guidance for movement of the M9 ACE.

It covers technical and physical characteristics, as

well as safety considerations, and prescribes the

materials and guidance required to prepare, load,

tie down, and unload the vehicle.

6-2. Safety

Besides the safety precautions contained in chap-

ter 3, the following areas apply:

a. All vessel equipment and gear should be

inspected before use.

b.

All stevedore slings and other items used in

loading and unloading operations should be

checked for their condition and capacity.

c. All other precautionary measures and safety

regulations peculiar to the loading/unloading site

or terminal will be observed.

d.

Vehicle fuel tanks must be drained and bat-

GENERAL

tery terminals disconnected.

e. Vehicle transmissions must be placed in the

neutral position and handbrakes must be set.

NOTE

When the M9 ACE is loaded on vessels

that are adequately ventilated by power

blowers, such as those commonly found on

the roll-on/roll-off (RORO) ships, fuel

tanks need not be drained.

6-3. Water Shipment

The M9 ACE can be transported by a great variety

of inland waterway cargo carriers, lighters, and

barges and by all seagoing cargo vessels.

NOTE

The methods described in this chapter for

lifting and securing the M9 ACE are

suggested procedures. Other methods of

handling and stowage may be used to

accomplish safe delivery without damage.

Section Il. LOADING AND SECURING

6-4. General Rules for Stowing

a.

General.

Whenever possible, vehicles should

receive the protection of below-deck stowage. In

general, good stowage of vehicles means having

them placed fore and aft as close together as

practical, with minimum spacing (about 4 to 6

inches) between outer vehicles and the sweat-

boards. Breakable parts or auxiliary equipment of

the vehicles should be adequately protected and

secured for shipment. If not shipped on the vehicle,

spare parts and on-equipment material should be

properly identified as to location or disposition

during shipment.

Vehicles in the ship’s hold

should be blocked in front, in rear, and on both

sides of the wheels so that the vehicles cannot

move. Individual vehicle blocks should be braced

to bulkheads, stanchions, and other vehicle blocks.

In addition, all vehicles should be lashed with wire

rope or chains to nearby padeyes, bulkheads, or

stanchions.

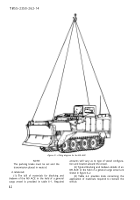

b. Lifting.

Correct lifting points on the vehicle

are the lifting eye provisions atop each of the four

extreme corners of the hull’s superstructure as

shown in figure 6–1.

c. Loading.

A check must be made to ensure the

hatch girder clearance of the specified vessel is at

least 107 inches (272 cm) for the unreduced M9

ACE or 98 inches (249 cm) for the reduced M9

ACE (cupola and exhaust stack removed). The

vehicle can be loaded over the beach or from piers

onto landing craft, beach discharge and amphibi-

ous lighters, landing ship tanks (LST), and landing

ship docks (LSD), under its own power or by crane

of adequate capacity. The vehicle can also be

loaded under its own power onto the deck of

barges from pierside when tidal conditions are

favorable and ramps are available. The vehicle can

be loaded onto seagoing vessels by shoreside or

floating cranes of adequate capacity. Jumbo booms

and heavy-lift ship’s gear may be used to load the

vehicle onto vessels. Also, the vehicle can be

driven or towed onto RORO vessels. Since the M9

ACE is amphibious, it can, under favorable condi-

tions, swim aboard, or debark from, offshore LST

and LSD. However, extreme caution is necessary

during amphibious operations because loss of free-

board may occur from excessive waves or while

turning on the water.

6-1

Back to Top