TM-9-2320-209-34-2-1 - Page 463 of 770

frame 2

TM 9-2320-209-34-2-1

1.

2.

3.

4.

5.

6.

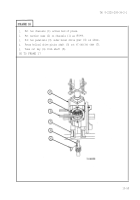

Check that two bearing cups (1) and two bearing cones (2) are not damaged.

Refer to para 10-8.

Using inside micrometer, measure inside diameter of bearing cones (2). Note

measurements.

Using out side micrometer, measure out side diameters of two differential case

halves (3). Note measurements.

Subtract measurement made in step 3 from measurement made in step 2.

Check that fit of bearing cones (2) on differential case halves (3) is within

limits given in table 10-5.

If fit of bearing cones is not within limits given,

get new parts in place of worn ones.

Mount each differential case half (3) in a lathe. Place dial indicator against

flange that mounts to helical drive gear (4). Check that runout flange of

differential case half is not more than 0.002 inch.

WARNING

Dry cleaning solvent is flammable. Do not use near an

open flame. Keep a fire extinguisher nearby when sol-

vent is used. Use only in well-ventilated places.

Failure to do this may result in injury to personnel and

damage to equipment.

If differential case half (3) runout is more than 0.002 inch, use lathe to

cut away only enough metal to bring runout within limit. Take off burrs

with a honing stone. Clean differential case half with dry cleaning solvent.

GO TO FRAME 3

Table 10-5. Differential Case and Bearing Wear Limits

(The letter T shows a tight fit.)

Size and Fit

Index of New Parts Wear Limit

Number

Item/Point of Measurement (inches) (inches)

2 and 3 Fit of bearing on case 0.0025T to 0.0050T 0.0020T

10-64

Back to Top