TM-9-2320-260-20 - Page 581 of 1337

TM 9-2320-260-20

I

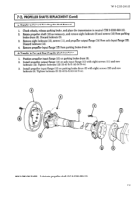

7-4. PROPELLER SHAFT REPAIR

THIS TASK COVERS:

a Disassembly

c. Assembly

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

MATERIALS/PARTS

Dust seal

Drycleaning solvent (Appendix C, Item 29)

GAA grease (Appendix C, Item 16)

Rags (Appendix C, Item 22)

REFERENCES (TM)

LO 9-2320-260-12

TM 9-2320-260-10

TM 9-2320-260-20P

• Parking brake set (TM 9-2320-260-10).

●

Propeller shaft removed (para. 7-2 or 7-3).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

NOTE

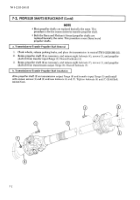

All propeller shafts are basically repaired the same.

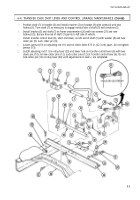

1. Loosen and slide back dust cap (2) on splined rod (1).

2. Remove splined rod (1) from splined tube (6).

3. Remove dust cap (2) from splined rod (1).

4. Remove washer (3), dust seal (4), and washer (5) from splined tube (6). Discard dust seal (4).

5. Remove lubrication fitting (8) from each yoke (7).

1.

2.

3.

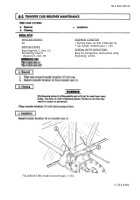

Inspect universal joint (9) for roughness, binding, looseness, and freeplay. Replace if damaged

(para. 7-5).

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

Clean the splines of splined rod (1), splined tube (6), and two lubrication fittings (8) with drycleaning

solvent. Dry parts with a clean rag.

Inspect splined rod (1) and splined tube (6) for breaks, cracks, bends, broken welds, and stripped

or crossed threads. Replace propeller shaft if damaged.

7-6

Back to Top