TM-9-2320-260-20 - Page 645 of 1337

TM 9-2320-260-20

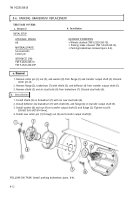

8-11. MASTER CYLINDER REPLACEMENT

THIS TASK COVERS:

a. Removal

b. Installation

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

All

TM 9-2320-260-10

MATERIALS/PARTS

Eight locknuts

TM 9-2320-260-20P

EQUIPMENT CONDITION

Screw-assembled lockwasher

●

Parking brake set (TM 9-2320-260-10).

Cotter pin

• Transfer to forward-rear axle propeller shaft

Antiseize tape (Appendix C, Item 30)

removed (para. 7-2).

a. Removal

1. Remove screw-assembled lockwasher (1) and open master cylinder hatch (2). Discard screw-

assembled lockwasher (1).

2. Remove four locknuts (15), screws (18), washers (17), and shield (14) from air-hydraulic

cylinder (16). Discard locknuts (15).

3. Remove return spring (5) from brake lever (4) and bracket (6).

4. Remove cotter pin (7), straight pin (9), and pushrod clevis (8) from brake lever (4). Discard cotter

pin (7).

5. Loosen jamnut (10) and remove pushrod clevis (8) from pushrod (12).

6. Disconnect hydraulic line (19) horn master cylinder (20) and air-hydraulic cylinder (16).

7. Remove four locknuts (13), screws (11), and master cylinder (20) from bracket (3). Discard

locknuts (13).

8. Visually inspect master cylinder dust boot (21). Replace if darn aged.

b. Installation

1. Install pushrod clevis (8) on pushrod (12).

2. Install master cylinder (20) on bracket (3) with four screws (11) and new locknuts (13).

3. Apply antiseize tape to male threads of hydraulic line (19).

4. Connect hydraulic line (19) on master cylinder (20) and air-hydraulic cylinder (16).

5. Install pushrod clevis (8) on brake lever (4) with straight pin (9) and new cotter pin (7).

6. Install return spring (5) on brake lever (4) and bracket (6).

7. Install shield (14) on air-hydraulic cylinder (16) with four washers (17), screws ( 18), and new

locknuts (15).

8-20

Back to Top