TM-9-2320-260-34-1 - Page 188 of 657

TM 9-2320-260-34-1

Section V. ENGINE REPAIR

3-49. ENGINE REPAIR MAINTENANCE INDEX

PARA.

NO.

TITLE

PAGE

NO.

3-50.

Cylinder Liners and Cylinder Block Maintenance

3-136

3-51.

Cylinder Head Repair

3-149

3-52.

Oil Pump Repair

3-168

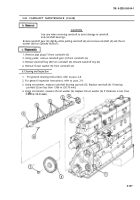

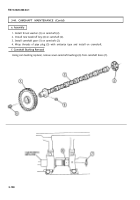

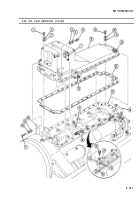

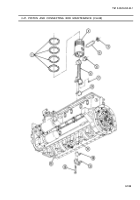

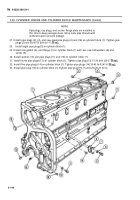

3-50. CYLINDER LINERS AND CYLINDER BLOCK MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TEST EQUIPMENT

Magnetic tester (Appendix B, Item 70)

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Cylinder liner puller (Appendix B, Item 76)

Cylinder liner driver (Appendix B, Item 77)

Cylinder liner clamp set (Appendix B, Item 13)

Gage block (Appendix B, Item 78)

Brush (Appendix B, Item 71)

Inside micrometer (Appendix B, Item 9)

Outside micrometer (Appendix B, Item 8)

Telescoping gage set (Appendix B, Item 74)

Depth micrometer (Appendix B, Item 16)

MATERIALS/PARTS

Cylinder liner packing set

(Appendix D. Item 481)

Two expansion plugs (Appendix D, Item 323)

a. Removal

Using cylinder

3-136

MATERIAIS/PARTS (Contd)

Liner shim set (Appendix D, Item 482)

Two lockwashers (Appendix D, Item 215)

Flange gasket (Appendix D, Item 65)

Detergent (Appendix C, Item 12)

Drycleaning solvent (Appendix C, Item 48)

Lubricating oil (Appendix C, Item 21)

Rags (Appendix C, Item 32)

Antiseize tape (Appendix C, Item 50)

REFERENCES (TM)

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

Crankshaft and main bearing removed (para. 3-48).

GENERAL SAFETY INSTRUCTIONS

l Compressed air source will not exceed 30 psi

(207 kPa).

l Eyeshields must be worn when cleaning with

compressed air.

l Keep fire extinguisher nearby when using

drycleaning solvent.

NOTE

l All six cylinder liners are removed the same. This procedure

covers one cylinder liner.

l Tag all cylinder liners for installation.

liner puller, remove cylinder liner (1) from cylinder liner bore (2).

Back to Top