TM-9-2320-260-34-1 - Page 212 of 657

TM 9-2320-260-34-1

3-51. CYLINDER HEAD REPAIR (Contd)

33.

34.

35.

36.

37.

38.

39.

40.

41.

Inspect four crosshead guides (1) for cracks, splits, or excessive wear. Replace crosshead guides (1) if

cracked, split, or excessively worn.

Measure outside diameter of four crosshead guides (1). Mark crosshead guide(s) (1) for replacement

if outside diameter is less than 0.432 in. (10.97 mm).

Measure height of crosshead guides (1). Mark crosshead guide(s) (1) for replacement if height is not

1.860-1.880 in. (47.24-47.75 mm).

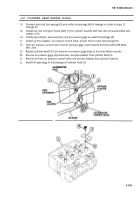

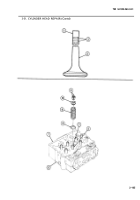

Inspect valve crossheads (2). Replace valve crosshead(s) (2) if defective.

Inspect adjusting screw threads (6) for damage. Replace valve crosshead(s) (2) if threads (6) are

damaged.

Inspect rocker lever contact area (3) for wear. Replace valve crosshead(s) (2) if rocker lever contact

area (3) is worn.

Set small bore gage at 0.4402 in. (11.181 mm) and attempt to insert into bore (5). Replace valve

crosshead (2) if bore gage goes into bore (5).

Inspect bore (5) for roundness by gaging at several points 90° apart. Replace valve crosshead (2) if

bore (5) is not round.

Replace valve crosshead (2) if counterbore depth (4) is not 0.1200-0.1400 in. (3.048-3.556 mm).

3-160

Back to Top