TM-9-2320-260-34-1 - Page 326 of 657

TM 9-2320-260-34-1

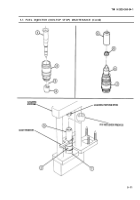

5-7. FUEL INJECTOR (NON-TOP STOP) MAINTENANCE

THIS TASK COVERS:

a. Disassembly

c. Assembly

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Vise (Appendix B, Item 38)

Torque wrench, 1/2-in. dr.

(Appendix B, Item 3)

Loading fixture

Cup retainer wrench (Appendix B, Item 21)

Injector body wrench (Appendix B, Item 23)

MATERIALS/PARTS

Injector overhaul repair kit

(Appendix D, Item 336)

MATERIALS/PARTS (Contd)

Drycleaning solvent (Appendix C, Item 48)

Cleaning cloth (Appendix C, Item 9)

Diesel fuel (Appendix C, Item 13)

REFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

l Parking brake set (TM 9-2320-260-10).

l Fuel injectors removed (para. 5-6).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

a. Disassembly

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do this may

result in injury to personnel.

CAUTION

Improper cleaning methods and use of unauthorized cleaning

solvents can damage equipment.

1. Clean exterior of injector (1) with drycleaning solvent.

CAUTION

Injector barrel and plunger are a matched pair (class fit). Do

not interchange. Do not touch internal parts unless hands are

moistened with diesel fuel. Failure to do this may result in

damage to equipment.

2. Remove plunger (2) and spring (3) from injector (1).

3. Install injector body wrench in vise.

4. Install injector (1) into body wrench so flat machined areas on injector (1) are secure in body wrench.

5. Using cup retainer wrench, loosen cup retainer (4).

6. Remove injector (1) from body wrench.

NOTE

Position injector so cup retainer is in an upward position. This will

prevent cup, barrel, and check ball from falling out of injector.

7. Remove cup retainer (4) from adapter (7).

8. Remove injector cup (5) from barrel (6). Discard injector cup (5).

5-6

Back to Top