TM-9-2320-260-34-2 - Page 267 of 863

TM 9-2320-260-34-2

15-53.

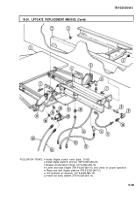

LIFTGATE MAIN FRAME MAINTENANCE (M820A2)

THIS TASK COVERS:

a. Removal

c. Installation

b. Cleaning and Inspection

lNITIAL SETUP

APPLICABLE MODELS

M820A2

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Hydraulic jack

REFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-260-10).

Liftgate lift frame removed (para. 15-52).

Liftgate cylinder removed (para. 15-59).

Liftgate control valve removed (para. 15-58).

Liftgate control linkage removed (para. 15-55).

GENERAL SAFETY INSTRUCTIONS

●

All personnel must stand clear during lifting

operations.

●

Ensure lifting capacity is greater than weight of

liftgate main frame.

a. Removal

1. Remove four lubrication fittings (4) from main frame (6).

2. Center hydraulic jack under main frame (6) and raise in place.

3. Remove twelve nuts (2) and screws (3) from main frame (6) and vehicle frame (1).

WARNIN G

All personnel must stand clear during lifting operations.

A swinging or shifting load may cause injury to personnel.

Ensure lifting capacity is greater than weight of liftgate main

frame. Failure to do so may result in injury to personnel or

damage to equipment.

NOTE

Two assistants will help with steps 4 and 5.

4. While steadying main frame (6) by control levers (5), remove main frame (6) from vehicle frame (1).

5. Remove main frame (6) from hydraulic jack.

b. Cleaning and Inspection

1. For general cleaning instructions, refer to para. 2-8.

2. For general inspection instructions, refer to para. 2-9.

All personnel must stand clear during Iifting operations.

A swinging or shifting load may cause injury to personnel.

Ensure Iifting capacity is greater than weight of liftgate main

frame. Failure to do so may result in injury to personnel or

damage to equipment.

15-206

Back to Top