TM-9-2320-260-34-2 - Page 471 of 863

TM 9-2320-260-34-2

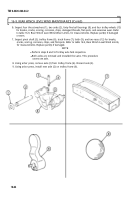

16-10. REAR WINCH CABLE TENSlONER MAINTENANCE (Contd)

I

5.

Inspect four thrust washers (1), two pins (2), sheaves (3), and bearings (4) for breaks, cracks,

scoring, chips, damaged threads, blocked lubrication passages, and excessive

wear. Refer to table

16-10, Rear Winch Tensioner Parts Wear Limits, for measurements. Replace part(s) if damaged

or worn.

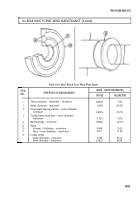

Table 16-10. Rear Winch Tensioner Parts Wear Limits.

ITEM

WEAR LIMITS/TOLERANCES

NO.

lTEM/POINT OF MEASUREMENT

INCHES

MILLIMETERS

1

Thrust washers – thickness - minimum

0.0615

1.562

2

Pins – diameter – minimum

1.2495

31.737

3

Sheaves

Hub – thickness – minimum

1.480

37.59

Bore - inner diameter – maximum

1.7497

44.442

4

Bearings – outer diameter – minimum

1.7495

44.437

1.

2.

3.

4.

5.

6.

7.

8.

9.

Install bearing (4) in sheave (3). Ensure bearing (4) is centered in bore.

Soak two new felt washers (8) in lubricating oil and install one felt washer (8) on each side of

bearing (4) in sheave (3).

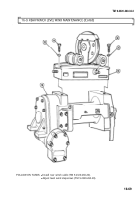

Position rod end of fork (7) through right end plate of frame (5).

Install sheave (3) and two thrust washers (1) in fork (7) and frame (5) with pin (2) and new cotter

pin (6). Ensure threaded end of pin (2) is facing out.

Install grease fitting (9) in pin (2).

Install bearing (4) in sheave (3). Ensure bearing (4) is centered in bore.

Soak two new felt washers (11) in lubricating oil and install one felt washer (11) on each side of

bearing (4) in sheave (3).

Position two thrust washers (1) and sheave (3) in left end of frame (5) and install with pin (2) and

new cotter pin (10). Ensure threaded end of pin (2) is facing out.

Install grease fitting (12) in pin (2).

16-72

Back to Top