TM-9-2320-260-34-2 - Page 469 of 863

TM 9-2320-260-34-2

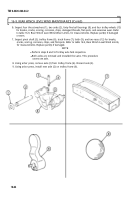

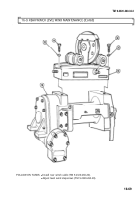

16-10. REAR WINCH CABLE TENSlONER MAINTENANCE

THIS TASK COVERS:

a. Disassembly

c.

Assembly

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

M816

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Inside micrometer (Appendix B, Item 9)

Outside micrometer (Appendix B, Item 8)

MATERIALS/PARTS

Two cotter-pins (Appendix D, Item 38)

Four felt washers (Appendix D, Item 529)

Lubricating oil (Appendix C, Item 21)

REFERENCES (TM)

LO 9-2320-260-12

TM 9-2320-260-20

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

●

Rear

winch cable removed (TM 9-2320-260-20).

. Rear tensioner assembly removed (para. 16-8).

I

a.

Disassembly

I

1. Remove grease fitting (7) from pin (8).

2. Remove cotter pin (1) and pin (8) from sheave (5) and frame (2). Discard cotter pin (1).

3.

Remove sheave (5) and two thrust washers (3) from frame (2).

4.

Remove two felt washers (4) and bearing (6) from sheave (5). Discard felt washers (4).

5. Remove grease fitting ( 16) from pin (15).

6. Remove cotter pin (9) and pin (15) from fork (10), sheave (13), and frame (2). Discard cotter pin (9).

7. Remove sheave (13) and two thrust washers (11) from fork (10).

8. Remove fork (10) from frame (2).

9. Remove two felt washers (12) and bearing ( 14) from sheave (13). Discard felt washers (12).

I

b. Cleaning and Inspection

1.

For general cleaning instructions, refer to para. 2-8.

2.

For general inspection instructions, refer to para. 2-9.

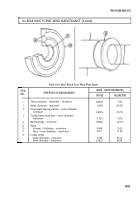

3. Inspect frame (2) for breaks, cracks, distortion, and broken or loose welds. Replace frame (2)

if damaged.

4.

Inspect fork (10) for breaks, cracks, misalinement of rod and plates, and broken or loose welds,

Replace fork (10) if damaged.

16-70

Back to Top