TM-9-2320-260-34-2 - Page 555 of 863

16-26. CRANE TURNTABLE MAINTENANCE (M816)

THIS TASK

COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

APPLICABLE MODELS

EQUIPMENT CONDITION

M816

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Lifting device

Eight washers (Appendix C, Item 56)

Four nuts (Appendix C, Item 24)

Four screws (Appendix C, Item 33)

MATERIALS/PARTS

Two lockwashers (Appendix D. Item 213)

•

•

•

•

Floodlight wiring harness removed

(TM 9-2320-260-20).

Hoist bevel gearcase removed (para. 16-25).

Hydraulic pump and support removed

(para. 16-24).

Crane gearcase removed (para. 16-28).

Crane boom elevating cylinders removed

(para. 16-14).

Crane gondola assembly removed (para. 16-22).

Hydraulic oil reservoir removed

(TM 9-2320-260-20).

Boom assembly removed (para. 16-18).

Eighteen locknuts (Appendix D, Item 173)

GENERAL SAFETY lNSTRUCTlONS

Eight lockwashers (Appendix D, Item 223)

GAA grease (Appendix C, Item 14)

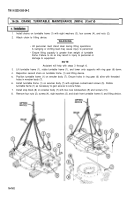

• All personnel must stand clear during lifting

AntiSeize

tape (Appendix C, Item 50)

operations.

•

Ensure lifting capacity is greater than weight of

REFERENCES (TM)

boom support.

TM 9-237

LO 9-2320-260-12

TM 9-2320-260-20

TM 9-2320-260-34P-2

NOTE

Assistant will help with step 1.

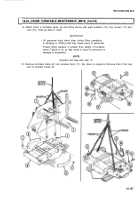

1. Attach chains and lifting device to boom support (1). Take up slack in chains.

2. Remove eighteen screws (2) and locknuts (3) from boom support (1) and turntable frame (6). Discard

locknuts (3).

WARNIN G

• All personnel must stand clear during Iifting operations.

A swinging or shifting load may cause injury to personnel.

• Ensure lifting capacity is greater than weight (30 lb (14 kg)) of

boom support. Failure to do so may result m injury to personnel

or damage to equipment.

NOTE

Assistant will help with step 3.

3. Remove boom support (1) from turntable frame (6).

4. Remove four screws (4) and right-hand guard (5) from turntable frame (6).

5. Remove four screws (7) an left-hand guard (8) from turntable frame (6).

6. Rotate turntable frame (6) 90° clockwise and remove two screws (14), lockwashers (13), and stop

block (12) from wrecker body (11). Discard lockwashers (13).

7. Remove socket-head screw (9) from ring•gear (10).

8. Rotate turntable frame (6) and remove next socket head screw (9) from ring gear (10). Repeat until

all eighteen socket-head screws (9) are removed.

16-156

TM 9-2320-260-34-2

•

•

•

•

Back to Top