TM-9-2320-272-24-1 - Page 133 of 1015

TM 9-2320-272-24-1

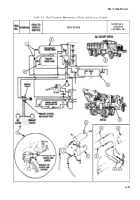

Table 2-1. Unit Preventive Maintenance Checks and Services (Contd).

PROCEDURE

46

Annual

Engine

2.

Check left-side engine mounting locknuts (1) and

compart-

right-side engine mounting screws (6) for looseness. If loose,

ment and

tighten 120-140 lb-ft (163-190 N•m).

cab

3.

Check two upper locknuts (4) securing left engine

(Contd)

mount (2). If loose, tighten 90 lb-ft (122 N•m). Check two

lower locknuts (3) for looseness. If loose, tighten 60 lb-ft

(82 N•m).

4.

Check two upper locknuts (7) securing right engine

mount (5) for looseness. If loose, tighten 90 lb-ft (122 N•m).

Check two lower locknuts (8) for looseness. If loose, tighten

60 lb-ft (81 N•m).

47

Annual

Rear

a, Inspect forward-rear and rear-rear axle housings and

suspension

differentials for cracks.

WARNING

Do not allow grease or oil to contact brake linings.

Linings can absorb grease and oil, causing early

glazing and very poor braking action. Failure to

comply could cause serious injury or death to

personnel.

b.

Tighten forward-rear and rear-rear axle drive flange

screws 80-105 lb-ft (108-142 N•m).

c.

Ensure all differential companion flange mounting

screws and U-joint mounting screws are tight. Tighten

companion flange mounting screws 30-40 lb-ft (41-54 N•m)

and U-joint mounting screws 90-110 lb-ft (122-149 N•m).

d.

Test spring seat bearing free play by placing jack under

spring seat bracket. Raise vehicle so spring moves freely

up and down in guide brackets. Put prybar between U-bolt

saddle and lift pin. Pull up on prybar. If there is free play,

adjust spring seat bearing (para. 3-169).

2-45

Back to Top