TM-9-2320-272-24-1 - Page 532 of 1015

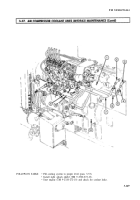

3-57. AIR

TM 9-2320-272-24-1

THIS TASK COVERS:

a. Removal

b. Cleaning and Inspection

c. Installation

INITIAL SETUP:

APPLICABLE MODELS

M939A2

TOOLS

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

General mechanic’s tool kit (Appendix E, Item 1)

EQUIPMENT CONDITION

MATERIALS/PARTS

• Hood raised and secured (TM 9-2320-272-10).

• Right splash shield removed (TM 9-2320-272-10).

Four seals (Appendix D, Item 625)

• Cooling system drained (para. 3-53).

Cap and plug-set (Appendix C, Item 14)

Antiseize tape (Appendix C, Item 72)

NOTE

When disconnecting water lines or hoses, plug ends and tag for

identification during installation.

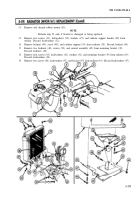

1.

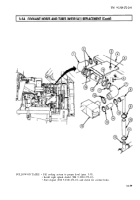

Disconnect two tubing nuts (10) and remove water outlet tube (7) and two seals (5) from air

compressor (11) and elbow (2) in cylinder head (1). Discard seals (5).

2.

Disconnect two tubing nuts (9) and remove water inlet tube (6) and two seals (4) from air

compressor (11) and elbow (3) in engine block (8). Discard seals (4).

3.

Remove elbow (2) from cylinder head (1) and elbow (3) from engine block (8).

1.

For general cleaning instructions, refer to para. 2-14.

2.

For general inspection instructions, refer to para. 2-15.

3.

Inspect tubes (6) and (7) for kinks, cracks, and bends.

4.

Replace all parts failing inspection.

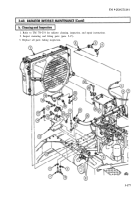

NOTE

Male pipe threads must be wrapped with antiseize tape before

installation.

1.

Install elbow (3) on engine block (8) and elbow (2) on cylinder head (1).

2.

Install water inlet tube (6) and two new seals (4) on air compressor (11) and elbow (3) on engine

block (8).

3.

Install water outlet tube (7) and two new seals (5) on air compressor (11) and elbow (2) on cylinder

head (1).

3-168

Back to Top