TM-9-2320-272-24-4 - Page 230 of 836

TM 9-2320-272-24-4

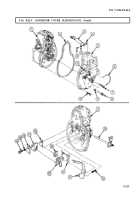

5-33. MANIFOLD PRESSURE COMPENSATOR MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

M939A2

TM 9-2320-272-24P

TOOLS

EQUIPMENT CONDITION

General mechanic’s tool kit (Appendix E, Item 1)

Fuel injection pump pretest performed (para. 5-32).

MATERIALS/PARTS

Manifold pressure compensator maintenance

kit (Appendix D, Item 423)

Silicone adhesive (Appendix C, Item 3)

a. Removal

1.

Remove safety wire (1) from screw (24) and protective cap (2). Discard safety wire (1).

NOTE

2.

3.

4.

5.

6.

7.

8.

It may be necessary to cut a slot on breakoff screws for removal.

Remove breakoff screw (22), screw (24), lockwashers (21) and (23), protective cap (2), and pull-

stop (3) from pull-stop cover (16). Discard breakoff screw (22) and lockwashers (21) and (23).

Remove O-ring (4) from pull-stop (3). Discard O-ring (4).

Remove nuts (20) and (19) from stop bolt (12).

Remove three screws (18) and lockwashers (17) from pull-stop cover (16). Discard lockwashers (17).

Remove breakoff screw (5), lockwasher (6), and pull-stop cover (16) from manifold pressure

compensator (7). Discard breakoff screw (5) and lockwasher (6).

Remove three screws (8), lockwashers (9), and washers (10) from manifold pressure compensator (7).

Discard lockwashers (9).

Remove breakoff screw (15), lockwasher (14), washer (13), and manifold pressure compensator (7)

from governor cover (11). Discard breakoff screw (15) and lockwasher (14).

b. Disassembly

1.

Remove cotter pin (28), washer (27), and lever (26) from stop bolt (12). Discard cotter pin (28).

2.

Remove stop bolt (12) and spring (29) from manifold pressure compensator (7).

3.

Remove round nut (34), washer (33), washer plate (32), diaphragm (31), and washer plate (30) from

stop bolt (12). Discard diaphragm (31).

4.

Remove O-ring (25) from manifold pressure compensator (7). Discard O-ring (25).

5-224

Back to Top