TM-9-2320-272-24-4 - Page 246 of 836

TM 9-2320-272-24-4

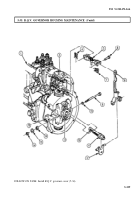

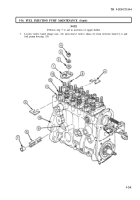

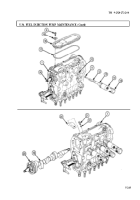

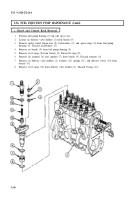

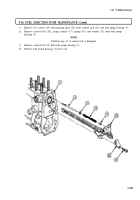

5-36. FUEL INJECTION PUMP MAINTENANCE

THIS TASK COVERS:

a. Camshaft Removal

b. Tappet and Plunger Removal

c. Barrel and Control Rack Removal

d. Cleaning and Inspection

e. Leakage Test

f.

Delivery Valve and Barrel Installation

g. Plunger and Control Rack Installation

h. Tappet and Spring Installation

i. Camshaft Installation

INITIAL SETUP:

APPLICABLE MODELS

M939A2

SPECIAL TOOLS

Two separation tubes (Appendix E, Item 119)

Side plug puller (Appendix E, Item 111)

Three tappet holders (Appendix E, Item 134)

Tappet spring compressor (Appendix E, Item 135)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 144)

Arbor press

MATERIALS/PARTS

Fuel injection pump repair kit (Appendix D,

Item 137)

Fuel injection pump maintenance kit

(Appendix D, Item 136)

MATERIALS/PARTS (Contd)

Sealing compound (Appendix C, Item 61)

GAA grease (Appendix C, Item 28)

Drycleaning solvent (Appendix C, Item 71)

Lubricating oil (Appendix C, Item 50)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

R.Q.V. governor housing removed (para. 5-35).

GENERAL SAFETY INSTRUCTIONS

Diesel fuel is flammable. Do not perform this task

near open flames.

Keep fire extinguisher nearby when using

drycleaning solvent.

Drycleaning solvent is flammable and toxic. Do

not use near open flame.

a. Camshaft Removal

WARNING

Diesel fuel is flammable. Do not perform fuel system procedure

near open flame. Injury to personnel may result.

Drycleaning solvent is flammable and toxic. Do not use near

open flame and always have a fire extinguisher nearby when

solvents are used. Use only in well-ventilated places, wear

protective clothing, and dispose of cleaning rags in approved

container. Failure to do this may result in injury or death to

personnel and/or damage to equipment.

CAUTION

Improper cleaning methods and use of unauthorized cleaning

solvents can damage equipment.

1.

Clean exterior of fuel pump housing (10) with drycleaning solvent.

2.

Using side plug puller, remove three side plugs (7) from fuel pump housing (10). Discard side plugs (7).

3.

Remove three spacer blocks (8) from side holes (9).

CAUTION

Keep cylinder parts together for replacement in their original

cylinder. Failure to do so may result in damage to fuel pump.

4.

Remove six nuts (4), lockwashers (3), spacer rings (2), and locking tabs (1) from studs (5) and delivery

valve holders (13). Discard lockwashers (3).

5-240

Back to Top