TM-9-2320-272-24-4 - Page 48 of 836

TM 9-2320-272-24-4

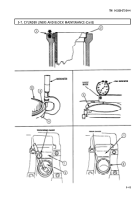

5-7. CYLINDER LINERS AND BLOCK MAINTENANCE (Contd)

22.

Install main bearing caps (2) in engine block (1) without crank or bearing shells.

23.

Measure main bearing bore diameter (3) horizontally, vertically, and diagonally with telescoping

gauge (4). Ensure bore diameter does not exceed 4.75 in. (120-663 mm).

NOTE

Pipe plugs, cup plugs, and suction flange plate are installed at this

time to keep passages clean. Wrap pipe plug threads with sealing

tape to prevent leakage.

24.

Install two cup plugs (9) in engine block (1).

25.

Install four pipe plugs (8) in block (1) and tighten according to table 5-6.

26.

Install eight pipe plugs (10) in block (1) and tighten according to table 5-6.

27.

Install new gasket (14) and suction flange plate (13) on engine block (1) with two new

lockwashers (12) and screws (11). Tighten screws (11) 10-15 lb-ft (14-20 N•m).

Table 5-6. Engine Block Pipe Plug Torque.

PIPE PLUG SIZE

1/8 in.

15

(20)

1/4 in.

30

(41)

3/8 in.

35

(47)

1/2 in.

45

(61)

3/4 in.

60

(81)

1-1/4 in.

75

(102)

1-1/2 in.

90

(122)

MINIMUM

LB-FT

(NM

MAXIMUM

LB-FT

(N•M)

20

(27)

35

(47)

45

(61)

55

(75)

70

(95)

85

(115)

100

(136)

NOTE

Most attempts to hone or deglaze cylinder liners provide worse

results than leaving them “as is”. Experience and laboratory

results indicate that liners do not need to be honed, rotated, or

deglazed to provide proper setting.

It is recommended that cylinder liners be inspected before

cleaning so defects can be clearly noted.

Inspect cylinder liners closely for any of the metal conditions

illustrated. If one liner has failed, then other liners in the same

engine are likely to have early signs of the same type of failure.

28.

Check cylinder liner (5) for scoring or vertical grooving (6) on the inside diameter indicating heavy

metal-to-metal contact of piston to cylinder liner (5). If scoring or vertical grooving (6) is present, tag

cylinder liner for replacement.

29.

Check cylinder liner (5) for cracks (7) indicated by magnetic detection. If cracks (7) are present, tag

cylinder liner (5) for replacement.

5-42

Back to Top