TM-9-2320-272-24-4 - Page 54 of 836

TM 9-2320-272-24-4

5-8. CRANKSHAFT AND MAIN BEARINGS MAINTENANCE

THIS TASK COVERS:

a. Removal

c. Installation

b. Cleaning and Inspection

d. End Play Clearance

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Main bearing cap puller (Appendix E, Item 108)

Outside micrometer (Appendix E, Item 80)

Vernier caliper (Appendix E, Item 159)

Torque wrench (Appendix E, Item 144)

Dial indicator (Appendix E, Item 36)

Hoist

Rubber-protected hooks

MATERIALS/PARTS

Crankshaft main bearing set

(Appendix D, Item 87)

Thrust ring set (Appendix D, Item 682)

Fourteen lockplates (Appendix D, Item 341)

Woodruff Key (Appendix D, Item 738)

Fourteen dowel rings (Appendix D, Item 100)

Lint-free cloth (Appendix C, Item 21)

GAA grease (Appendix C, Item 28)

Lubricating oil (Appendix C, Item 50)

Drycleaning solvent (Appendix C, Item 71)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

Connecting rod and pistons removed (para. 5-10).

GENERAL SAFETY INSTRUCTIONS

l

Keep fire extinguisher nearby when using

drycleaning solvent.

l

Drycleaning solvent is flammable and toxic. Do

not use near an open flame.

l

When cleaning with compressed air, wear

eyeshields and ensure source pressure does not

exceed 30 psi (207 kPa).

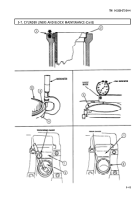

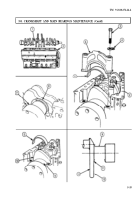

a. Removal

1.

Turn engine block (1) upside down.

2.

Bend down lockplate tab (8) and remove two screws (7) from seven main bearing caps (9). Discard

lockplates (8).

NOTE

Tag all bearing caps and bearing shells for installation.

3.

Remove main bearing caps (9) from engine block (1) with main bearing cap puller.

4.

Remove lower half bearing shell (10) from main bearing caps (9). Discard lower half bearing shell (10).

5.

Remove lower half of thrust ring (4) from crankshaft near journal (5). Discard thrust ring (4).

6.

Carefully remove crankshaft (6) from engine block (1) using hoist and rubber-protected hooks (11).

Place crankshaft (6) on clean, flat surface.

7.

Remove upper half bearing shells (2) from engine block (6). Discard upper half bearing shells (2).

8.

Remove fourteen dowel rings (3) from engine block (1). Discard dowel rings (3).

9.

Remove upper half of thrust ring (4) from engine block (1). Discard thrust ring (4).

5-48

Back to Top