TM-9-2320-272-24-4 - Page 70 of 836

TM 9-2320-272-24-4

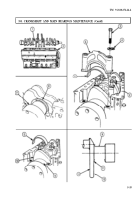

5-10. PISTON AND CONNECTING ROD MAINTENANCE

THIS TASK COVERS:

a.

Connecting Rod Side Clearance Check

b. Removal

c.

Disassembly

d.

Cleaning and Inspection

e.

Assembly

f.

Installation

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

SPECIAL TOOLS

Piston ring groove gauge (Appendix E, Item 97)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 144)

Telescoping gauge (Appendix E, Item 136)

Outside micrometer (Appendix E, Item 80)

Inside micrometer (Appendix E, Item 82)

Piston ring expander (Appendix E, Item 96)

Arbor press

Feeler gauge

Soft-faced hammer

Vise

Tape-protected tool

a. Connecting Rod Side Clearance Check

1.

2.

3.

MATERIALS/PARTS

Twelve bearing shells (Appendix D, Item 14)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

Camshaft and gear removed (para. 5-9).

GENERAL SAFETY INSTRUCTIONS

Gloves must be worn when handling hot pistons.

NOTE

Connecting rod should have free movement at crank journal.

Check with hand pressure first. Tap lightly with soft-faced

hammer only if necessary.

Move connecting rod (1) up and down on crank journal (3) and measure clearance with feeler gauge.

Clearance should be 0.0045-0.13 in. (0.11-0.33 mm). Record clearance of all six connecting rods for

reassembly.

NOTE

If clearance is not 0.0045-0.13 in. (0.11-0.33 mm) or rod will not

move, continue with steps 2 and 3.

Remove cap (2) and check for improper bearing size, dirt, or burrs.

Install cap (2) as outlined in task f.

5-64

Back to Top