TM-9-2320-272-24-4 - Page 64 of 836

TM 9-2320-272-24-4

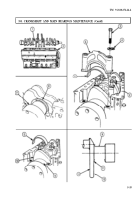

5-9. CAMSHAFT AND GEAR MAINTENANCE

THIS TASK COVERS:

a.

Check Backlash

b.

Removal

c.

Disassembly

d.

Cleaning and Inspection

e.

Assembly

f.

Installation

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

SPECIAL TOOLS

Telescoping gauge (Appendix E, Item 136)

Cam bushing replacement tool (Appendix E,

Item 26)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Dial indicator (Appendix E, Item 36)

Puller kit (Appendix E, Item 102)

Outside micrometer (Appendix E, Item 80)

Vernier caliper (Appendix E, Item 159)

Brass rod

a. Check Backlash

MATERIALS/PARTS

Seven cam bushings (Appendix D, Item 34)

Camshaft bushing (Appendix D, item 33)

Lubricating oil (Appendix C, Item 50)

Drycleaning solvent (Appendix C, Item 71)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Engine oil pan removed (para. 4-22).

l

Piston and connecting rod installed (para. 5-10).

GENERAL SAFETY INSTRUCTIONS

l

Keep tire extinguisher nearby when using

drycleaning solvent.

l

Drycleaning solvent is flammable and toxic. Do

not use near an open flame.

1.

Attach dial indicator to engine block (3) and rotate camshaft gear (2) as far as it will freely move

and hold it in place. Ensure crankshaft gear (1) does not move.

2.

Position dial indicator arm to camshaft gear (2) tooth and set dial indicator to zero.

3.

Rotate camshaft gear (2) in opposite direction and read backlash measurement as rotation stops. If

backlash is not 0.002-0.020 in. (0.05-0.51 mm), replace camshaft gear (2).

NOTE

Normal backlash is 0.0045-0.0105 in. (0.114-0.267 mm) on new

gear with a minimum of 0.002 in. (0.05 mm).

b. Removal

Rotate camshaft gear (2) and camshaft (4) slightly and remove from engine block (3).

CAUTION

Use care when removing camshaft to avoid damaging bearings.

5-58

Back to Top