TM-9-2320-279-20-2 - Page 100 of 938

TM 9-2320-279-20-2

Brake and Air System Maintenance Instructions (Cont)

11-7.

BRAKE INSPECTION ADJUSTMENT (CONT).

(3)

(4)

(5)

(6)

(7)

(8)

(9)

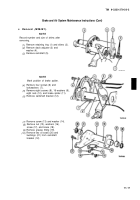

NOTE

Use 80 to 90 psi (552 to 620 kPa) air

pressure for inspection.

Front brake chamber is shown. Rear

brake chamber is measured in the

same manner.

Some vehicles have manually

adjusted slack adjusters. Others

have automatic slack adjusters.

Perform steps (3) through (6) for

manually adjusted slack adjusters.

Perform steps (7), (8), and (9) for

automatic slack adjusters.

Start engine and build up air pressure

(TM 9-2320-279-10).

Soldier A holds brake treadle down

while Soldier B measures between

center of yoke pin (1) and chamber

bracket (2). Record measurement.

With brake treadle released, measure between center of yoke pin (3) and chamber bracket (2).

Record measurement.

Subtract brake released measurement from brake applied measurement. If difference is 1-3/4

in. (44.5 mm) or more for front brakes or 2 in. (50.8 mm) or more for rear brakes, adjust all

brakes.

Release spring and service brake and check

that automatic slack adjuster’s installation

indicator (4) is within slot. If slack adjuster

fails this inspection, refer to para 11-5.1

(front) or para 11-6.1 (rear).

Remove cotter pin (5) and clevis pin (6).

Discard cotter pin (5). Check that yoke (7)

hole and slack adjuster (8) hole remain in

alinement. If brake chamber yoke (7)

retracts into the brake chamber, it fails

inspection and must be readjusted. Refer to

para 11-5.1 (front) or para 11-6.1 (rear).

Install clevis pin (6) and new cotter pin (5).

11-20

Change 2

Back to Top