TM-9-2320-280-20-2 - Page 808 of 951

11.

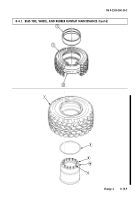

Lay tire (1) flat.

WARNING

• Do not use runflat compressor if compressor strap is frayed or damaged.

Inspect the tool’s pivot points and bearings and ensure runflat is free of

grease and runflat compressor strap is centered around runflat. Failure

to do so could cause injury to personnel.

• Any oil on runflat compressor belt or handle could result in personnel

injury or damage to equipment. Wipe any oil off from belt or handle.

NOT E

Perform steps 12 and 13 when using runflat compressor P/N J39250.

Perform steps 14 and 15 when using runflat compressor P/N 528236.

11.1. Make sure gears and pivot points on runflat compressor (3) or (6) have a light coat of oil to ensure

ease of operation and prevent from rust.

12.

Position runflat compressor (3) on runflat (2) so that runflat compressor hex drive (4) is facing up

and strap (5) is centered around runflat (2).

NOT E

Compress runflat by rotating hex drive in either direction. Rotate hex

drive opposite to loosen.

13.

Using runflat compressor (3), compress runflat (2).

14.

Position runflat compressor (6) on an outer edge of runflat (2) with handle assembly (7) facing up

and strap (8) centered around runflat (2).

NOT E

Compress runflat by rotating the handle assembly in a clockwise

direction. Rotate handle assembly counterclockwise to loosen.

15.

Using runflat compressor (6), compress runflat (2).

NOT E

• It may be necessary to use a tire spoon and tire soap to remove

runflat from tire.

• When using runflat compressor P/N 528236, handle may need to be

removed before removing runflat.

16.

Remove runflat (2) from tire (1) and remove runflat compressor (3) or (6) from runflat (2).

17.

Remove two lubricant packets (9) and adhesive tape (10) from runflat (2) if installed.

TM 9-2320-280-20-2

8 - 1 8

Change 2

8 - 5 . RADIAL TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE (ALL EXCEPT M1123

AND “A2” VEHICLES) (Co n

t ’ d )

RUNFLAT COMPRESSOR (P/N 528236)

RUNFLAT COMPRESSOR (P/N J39250)

Back to Top