TM-9-2320-280-20-2 - Page 804 of 951

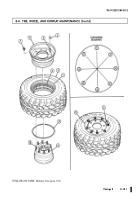

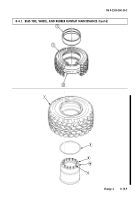

8-4.1. BIAS TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE (Cont'd)

TM 9-2320-280-20-2

8-14.10

Change 3

WARNING

Never intermix bias and radial rim assemblies. Damage to

equipment may result causing injury to personnel.

NOTE

Before installing tire on inner rim half, inspect tire sidewalls for a

“paint dot”. Paint dots are often painted on tires to indicate the

tire’s light spot, for balancing purposes. If paint dot is present,

position tire on rim halves so that paint dot is aligned with insert

hole on outer rim half.

14.

Center runflat (6) and runflat spacer (5) in tire (1). Carefully lower tire (1) over inner rim

half (8). Check to ensure O-ring (7) has not been disturbed.

15.

Ensure runflat (6) and runflat spacer (5) are not binding on flat portion of inner rim half (8).

Runflat (6) and runflat spacer (5) should clear inner rim half (8).

16.

Install valve core (9) in valve bore (10).

NOTE

Perform step 17 only if valve bore and insert were removed.

17.

Install insert (11), O-ring (12), and locknut (13) on outer rim (3). Apply sealing compound to valve

bore (10) and install valve bore (10) on insert (11). Tighten locknut (13) to 40-60 lb-in. (5-7 N

•

m).

Tighten valve bore (10) to 25-30 lb-ft (34-41 N

•

m).

18.

Install outer rim half (3) on inner rim half (8).

CAUTION

Tighten locknuts gradually to avoid bent and broken studs, or

damage to wheel components.

19.

Install outer rim half (3) to inner rim half (8) with twelve locknuts (2).

~

~

2

3

4

5

6

7

8

1

9

12

11

13

3

10

Back to Top