TM-9-2320-280-34 - Page 1026 of 1258

TM 9-2320-280-34

21 - 4.

FRAME INSPECTION AND REPAIR

This task covers:

a.

General Information

d.

Preparation and Materials

b

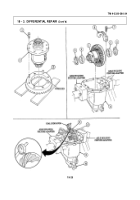

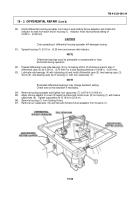

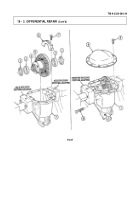

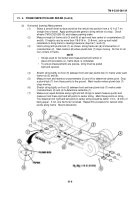

Powertrain Lift Sling Installation

e.

Repair Procedures

c.

Inspection

f.

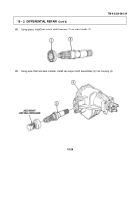

Powertrain Lift Sling Removal

INITIAL SETUP:

Tools

Equipment Condition

General mechanic's tool kit: Automotive

Vehicle stripped of mission and stowed equipment

(Appendix G, Item 1)

(TM 9-2320-280-10).

Vehicle undercarriage clean and free of mud and

Materials/Parts

debris.

Cotter pin (Appendix E, Item 8)

Powertrain lift sling (Appendix C, Fig.

14, 15)

General Safety Instructions

When using power-driven equipment to straighten

References

frames, all personnel must stand clear.

TM 9-2320-280-10

Shim material must be under jackstands.

TM 9-2320-280-20

Ensure shoulder bolts have a raised metal

TM 9-2320-280-24P

“10.9" material strength indicator on the head

TM 9-237

of the bolts

TB 750-98-23

TM 43-0139

Maintenance Level

General support

a.

General Information

1.

Frame rails are constructed by arc-welding two 'C" channels of preformed steel together to form a box-

cross section.

2.

Frame rails are internally reinforced at bolt hole locations by bushings or full cross-section spacers to

prevent channels from collapsing from attaching load.

NOTE

Crossmembers and crossmember brackets must be replaced if

damaged.

3.

The frame is made by bolting two non-identical frame rails to crossmembers.

Crossmembers are held

to more stringent dimensional tolerances and must be replaced if damaged.

4.

The type of repairs attempted will vary considerably depending on equipment, type of facilities, and

skill of available personnel.

Also the choice of procedures will be influenced by parts supply status and

the operational situation.

5.

Mechanical forces involved in frame straightening can lead to safety problems, which all personnel

must constantly keep in consideration.

6.

The removal of frame constraints (loosening of crossmember and bracket fastenings) is critical to allow

enough freedom of movement when straightening frame.

7.

The objective of a repair procedure is to return the vehicle to a mission-safe (operationally and

mechanically) condition within a reasonable time and cost expenditure.

8.

For ease of frame maintenance, use powertrain lift sling.

(Refer to para.

b.)

21-2

Back to Top