TM-9-2320-280-34 - Page 220 of 1258

3 - 2 5 . ENGINE INSTA L L ATION (6.5 L) (Cont’d)

TM 9-2320-280-34

3 - 1 5 8

Change 1

NOT E

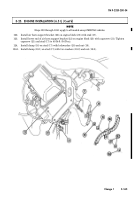

• Perform steps 75 through 86 for vehicles equipped with Neihoff

100 amp alternator only.

• Ensure terminals are clean before connections are made.

7±5±

.

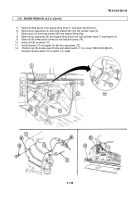

Install positive cable (10) on positive stud (9) with washer (12), lockwasher (13), and nut (14). Ti±g±h±t±e±n

nut (14) to 10-15 lb-ft (14-20 N

•

m±)

7±6±

.

Install ground cable (5) on alternator (6) with washer (3), lockwasher (2), and capscrew (1). Ti±g±h±t±e±n

capscrew (1) to 8-12 lb-ft (11-16 N

•

m±)±

.

7±7±

.

Position drivebelt (7) on pulley (8).

7±8±

.

Install rubber boots (11) and (4) over cables (5) and (10).

7±9±

.

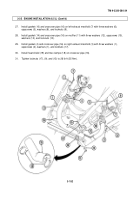

Apply sealing compound to threads of capscrew (18).

8±0±

.

Install voltage regulator (19) on alternator (6) with lockwasher (17) and capscrew (18). Ti±g±h±t±e±n

capscrew (18) to 88-94 lb-in. (10-11 N

•

m±)

8±1±

.

Install two washers (22), lockwashers (21), and screws (20) on voltage regulator (19) and

a±l±t±e±r±n±a±t±o±r (6). Tighten screws (20) to 30-34 lb-in. (3-4 N

•

m±)

8±2±

.

Install washer (24), lead (25), and nut (26) on terminal (23). Tighten nut (26) to 18-22 lb-in.

(2.0-2.5 N

•

m). Slide rubber boot (27) over terminal (23).

8±3±

.

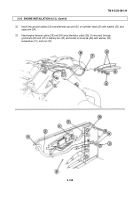

Connect regulator connector (34) to alternator connector (33).

8±4±

.

Install washer (38), lead 5A (37), and nut (36) on red (energize) terminal (39). Tighten nut (36) to

23-27 lb-in. (2.6-3.0 N

•

m). Slide rubber boot (35) over terminal (39).

8±5±

.

Install washer (29), lead 2A (30), and nut (31) on yellow (AC) terminal (28). Tighten nut (31) to

18-22 lb-in (2.0-2.5 N

•

m). Slide rubber boot (32) over terminal (28).

8±6±

.

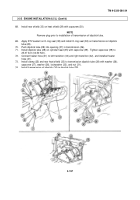

Connect regulator plug (16) to voltage regulator (19).

Back to Top