TM-9-2320-280-34 - Page 501 of 1258

9-3.

DIFFERENTIAL OUTPUT SHAFT SEAL REPLACEMENT

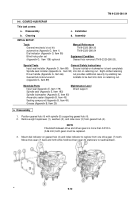

INITIAL SETUP:

To o l s

____

General mechanic's tool kit:

automotive (Appendix G, Item 1)

Special To o l s

__________

Axle shaft and seal installer

(Appendix G, Item 79)

M a t e r i a l s / P a rt s

_____________

Seal washer (Appendix E, Item 198)

Locknut (Appendix E, Item 46)

Sealing compound (Appendix B, Item 50)

Manual Refere n c e s

_______________

TM 9-2320-280-24P

Equipment Condition

_________________

Service brake rotors removed (TM 9-2320-280-20).

Maintenance Level

_______________

Direct support

This task covers:

a.

Removal

b.

Installation

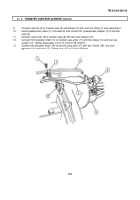

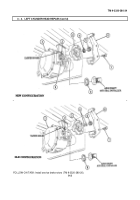

NOTE

New configuration side mounting bracket allows for output shaft

seal replacement without bracket removal. Inspect bracket to

determine output shaft seal clearance. If clearance exists, perform

steps 2 through 4. If clearance does not exist, perform steps 1

through 4.

1.

Remove old configuration side mounting bracket (9) (para. 12-16).

2.

Remove locknut (5), seal washer (4), and output flange (3) from output shaft (2). Discard seal

washer (4), and locknut (5).

3.

Remove two capscrews (7) and brake adapter (6) from differential (1).

4.

Remove output shaft seal (8) from differential (1).

NOT E

New configuration side mounting bracket allows for output shaft

seal replace-ment without bracket removal. If side mounting

bracket was not removed, perform steps 2 through 4. If bracket was

removed, perform steps 1 through 4.

1.

Install new configuration side mounting bracket (9) (para. 12-16).

2.

Using axle shaft and seal installer, install output shaft seal (8) in differential (1).

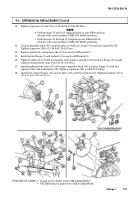

CAUTION

Apply a liberal amount of thread sealing compound to the tapped holes

of differential. To allow adequate coating of threads, install capscrews

shortly after applying thread sealing compound. Failure to do this

could allow capscrews to loosen and cause damage to differential.

3.

Apply sealing compound to tapped holes of differential (1) and install brake adapter (6) on

differential (1) with two capscrews (7). Tighten capscrews (7) to 110-140 lb-ft (149-190 N

•

m).

4.

Install output flange (3), seal washer (4), and locknut (5) on output shaft (2). Tighten locknut (5) to

170 lb-ft (231 N

•

m).

b. Installation

a. Removal

TM 9-2320-280-34

9 - 2

Change 1

Back to Top