TM-9-2320-285-24-1 - Page 422 of 987

TM 9-2320-285-24-1

2-35.

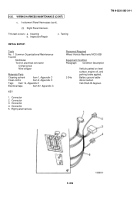

WIRING HARNESS MAINTENANCE (CONT)

b.

Chassis Harnesses (cont).

(2)

Rear Chassis Harness (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION/REPAIR (cont)

2

b.

Rear chassis

Inspect

Repair if insulation frayed

(cont)

harness (2)

or conductor broken.

Wrap

electrical tape over frayed

insulation.

If broken

conductor is accessible,

cut a length of same gage

wire and splice using in-

sulated splice connector;

if wire is not accessible,

replace harness (notify

direct support maintenance)

TESTING

3

Cab

Rear chassis

Test

Use multimeter set to Xl ohms

harness (2)

continuity

range (refer to electrical

system wiring schematic);

refer to step (2) above for

repair of broken conductor

4

Cab,

Connector (1)

Connect

As tagged

inside

5

Battery

Battery ground

Connect

Para 2-34a

box

cable

6

Cab tilt

Cab

Lower

To normal operating

position

pump

7

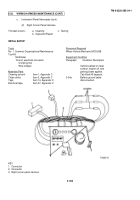

Cab

a.

Key switch

Turn on

b.

Lights,

Check

If lights, controls, or

controls, and

operation

indicators do not operate,

indicators

refer to para 2-17 thru

2-23 for troubleshooting

procedures

c.

Key switch

Turn off

2-399

Back to Top