TM-9-2320-346-10 - Page 297 of 1184

NOTE

While moving LHS hook arm rearward, ensure winch hydraulic hoses are

not trapped or damaged. Operating equipment with trapped or damaged

hydraulic hoses will cause damage to equipment.

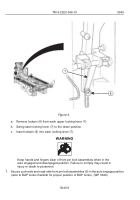

15. Position HOOK ARM switch (23) to UNLOAD and release when hook arm cylinders

(24) are extended approximately 6 in. (15 cm).

16. Position MAIN FRAME switch (25) to UNLOAD and release when main frame has

moved rearward and winch cable hook (26) is about 2 ft. (61 cm) above bridge bay

lifting eye (27).

WARNING

•

Always wear protective gloves when handling winch cable. Never let

cable run through hands. Frayed cables can cut severely. Failure to

comply may result in injury or death to personnel.

•

Never operate winch with less than five wraps of cable on winch

drum. Failure to comply may result in injury or death to personnel.

17. While an assistant maintains tension on winch cable, position remote WINCH switch

(28) to OUT and release when winch cable hook (26) can be attached to bay lifting eye

(27).

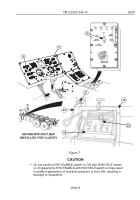

CAUTION

To prevent damage to bridge bay, pick up bridge bay only on the spreader

cable and stationary hook eye end of bridge bay.

18. Attach winch cable (29) to bridge bay.

a.

Winch cable hook (26) should face rear with throat up.

b.

Hook latch (30) should be closed.

WARNING

All personnel should stay clear of vehicle during bridging operations.

Failure to comply may result in injury or death to personnel.

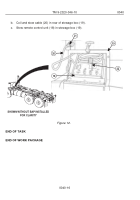

19. Position MAIN FRAME switch (25) to LOAD and release when there is no cable slack.

TM 9-2320-346-10

0040

0040-11

Back to Top