TM-9-2320-361-20 - Page 349 of 1207

TM 9-2320-361-20

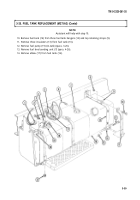

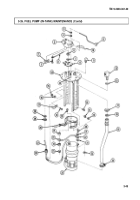

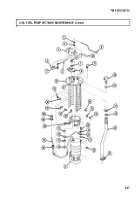

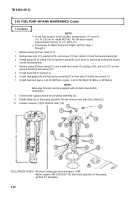

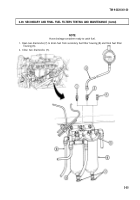

3-26. FUEL PUMP (lN-TANK) MAINTENANCE (Contd)

d. Cleaning and Inspection

Clean and inspect all fuel pump assembly parts for cracks, holes, and stripped threads. Replace

damaged parts.

e. Assembly

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

3-46

Install ground strap (22) on pump (25) and clamp assembly (28) with four new lockwashers (21),

two screws (20), and nuts (23).

Install hose assembly (19) on pump (25) with clamp (24).

Install new “O” ring (13) and fitting (12) on plate and bracket (32) with new lockwasher (17) and

nut (18).

NOTE

Male pipe threads must be wrapped with antiseize tape before

installation.

Install hose assembly (19) on fitting (12).

Install elbow (11) on plate and bracket (32).

NOTE

Before installing pump, measurement “A” must be 14.1 in. (36 cm)

for model M275A2. For all other models, measurement must be

15.1 in. (38.4 cm).

Install pump (25) on clamp assembly (28) and position pump (25) up or down in plate and

bracket (32) to give correct measurement.

Remove pump (25) from clamp assembly (28) and install clamp assembly (28) on plate and

bracket (32) with two screws (14), washers (16), and nuts (15).

Install pump (25) on clamp assembly (28).

Install clamp (31) on wire retainer (26) with screw (14), washer (16), and nut (15).

Install new gasket (8) on plate and bracket (32) and position fuel pump wire (27) through center

hole in plate and bracket (32) and new gasket (8).

Install recessed washer (29), new gasket (30), and wire retainer (26) on plate and bracket (32) with

new lockwasher (7) and nut (6).

Install fuse (2) on terminal cover (3).

Install fuel pump wire (27) on terminal cover (3) with screw (1).

Install terminal cover (3) and new locktab (10) on plate and bracket (32) and gasket (8) with three

new lockwashers (4) and nuts (5).

Install new lead seal (9) on stud (33) with lead seal press.

Back to Top