TM-9-2320-361-34 - Page 271 of 764

TM 9-2320-361-34

I

11-3. PARKING AND SERVICE BRAKESHOE REPAIR

THIS TASK COVERS:

a. Disassembly

c. Assembly

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

All

TM 9-2320-361-20

TOOLS

TM 9-2320-361-34P

General mechanic’s tool kit

(Appendix B, Item 1)

EQUIPMENT CONDITION

Parking or service brakeshoes removed

Brake reliner (Appendix B, Item 12)

(TM 9-2320-361-20).

MATERIALS/PARTS

GENERAL SAFETY INSTRUCTIONS

Service brakeshoe parts kit

●

Do not use compressed air or dry brush for

(Appendix F, Item 190)

cleaning in areas where asbestos brake lining dust

Parking brakeshoe parts kit

may accumulate.

(Appendix F, Item 189)

●

Keep fire extinguisher nearby when using

Drycleaning solvent (Appendix C, Item 24)

drycleaning solvent.

NOTE

●

Parking and service brakeshoes are repaired

basically the same. This task covers service

brakeshoe repair.

●

All service and parking brakeshoe linings must

be replaced as matched sets.

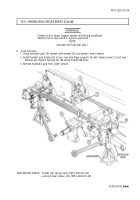

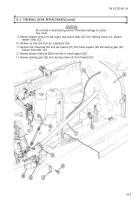

Remove fourteen rivets (4) and lining (2) from service brakeshoe (1). Discard rivets (4).

I

b. Cleaning and Inspection

I

WARNING

●

Do not use compressed

air

or

dry

brush

for

cleaning

when

working in areas of vehicle where asbestos brake lining dust may

accumulate. Remove asbestos dust and other residue from these

areas using a soft bristle brush or cloth soaked with water.

Breathing asbestos dust may cause injury to personnel.

●

Drycleaning

solvent

is

flammable

and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury or death to personnel.

1. Clean brakeshoe (1) with water and soft bristle brush. Allow to air dry. Clean with drycleaning

2. Check brakeshoe (1) for cracks, warps, flat spots on faces, and out-of-round rivet holes (3). Replace if

cracked, warped, flat, or holes are out-of-round.

solvent.

c. Assembly

Install lining

(2)

on service brakeshoe (1) with fourteen new rivets

(4).

11- 4

Back to Top