TM-9-2320-366-20-3 - Page 905 of 1396

TM 9-2320-366-20-3

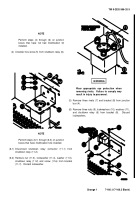

7-28. M1089 JUNCTION BOX ASSEMBLY REPLACEMENT/REPAIR

This task covers:

a. Removal

b. Disassembly

c. Assembly

d. Installation

e. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Crane erected (TM 9-2320-366-10-1).

Engine shut down (TM 9-2320-366-10-1).

Batteries disconnected (para 7-57).

Tools and Special Tools

Tool Kit, Genl Mech (Item 46, Appendix C)

Goggles, Industrial (Item 15, Appendix C)

Drill, Portable, Electric (Item 7, Appendix C)

Drill, Set Twist (Item 6, Appendix C)

Tool Kit, Blind Rivet (Item 44, Appendix C)

Tool Kit, Electrical (Item 45, Appendix C)

Materials/Parts

Dispenser, Pressure Sensitive Adhesive Tape

(Item 20, Appendix D)

Insulation Sleeving, Electrical (Item 29,

Appendix D)

Ties, Cable, Plastic (Item 69, Appendix D)

Varnish, Oil (Item 70, Appendix D)

Adhesive (Item 5, Appendix D)

Nut, Conduit (3) (Item 124, Appendix G)

Nut, Conduit (2) (Item 125, Appendix G)

Lockwasher (16) (Item 91, Appendix G)

Lockwasher (4) (Item 94, Appendix G)

Lockwasher (Item 92, Appendix G)

Rivet, Blind (Item 255, Appendix G)

Lockwasher (Item 93, Appendix G)

Modification Kit, Junction Box (Item 31.1, Appendix D)

Rag, Wiping (Item 50, Appendix D)

a. Removal.

NOTE

Remove plastic cable ties as required.

(1) Loosen four screws (1) on junction box (2).

(2) Open cover (3) on junction box (2).

Change 1

7-159

Back to Top