TM-9-2320-386-24-1-1 - Page 14 of 1078

TM 9-2320-386-24-1-1

0001 00

GENERAL INFORMATION

SCOPE

a.

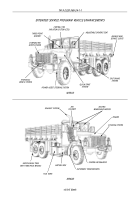

This manual contains instructions for servicing and maintenance of 2-1/2-ton, 6x6, M44A2 series

vehicles which have been rebuilt through the Extended Service Program (ESP). These vehicles are:

(1)

M35A3, Cargo Truck, WO/W and W/W (Fixed Side)

(2)

M35A3C, Cargo Truck, WO/W and W/W (Dropside)

(3)

M36A3, Cargo Truck, WO/W and W/W (Long Wheelbase)

b.

The material presented here provides unit, direct support, and general support maintenance

personnel with information and procedures needed to provide the safest and most efficient operation and

servicing of these vehicles. This information includes:

(1)

Vehicle limitations.

(2)

The function of unique controls.

(3)

Cautions and warnings to operators regarding safety to personnel and equipment.

(4)

Troubleshooting procedures to be followed by unit, direct support, and general support

maintenance personnel if the vehicle malfunctions.

(5)

Unit maintenance checks and services.

(6)

Repair procedures to be followed by unit, direct support, and general support maintenance

personnel.

c.

This manual contains unit, direct support, and general support procedures unique to M44A3, ESP

series vehicles. Refer to TM 9-2320-361-20 for unit maintenance procedures or TM 9-2320-361-34 for direct

support and general support procedures common to M44A2 series vehicles.

MAINTENANCE FORMS, RECORDS, AND REPORTS

Department of the Army forms and procedures used for equipment maintenance will be those prescribed

by DA Pam 738-750, The Army Maintenance Management System (TAMMS).

REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR’S)

If the design of your vehicle needs improvement, let us know. If your vehicle is in proper operating

condition and there are problems with vehicle or equipment performance, send us an EIR. You, the user,

are the only one who can tell us what you don’t like about your equipment. It is not necessary to show a

new design or a better way to perform a procedure. Just let us know why you don’t like the design or

performance. Put in on an SF 368 (Quality Deficiency Report). Mail it to us at: Commander, U.S. Army

Tank-automotive and Armaments Command, ATTN: AMSTA-IM-MMAA, Warren, Michigan 48397-5000.

We’ll send you a reply. You may also mail, fax or email your letter, DA Form 2028, or DA Form 2028-2

direct to: AMSTA-LC-CI/TECH PUBS, TACOM-RI, 1 Rock Island Arsenal, Rock Island, IL 61299-7630. The

email address is TACOM-TECH-PUBS@ria.army.mil. The fax number is DSN 793-0726 or Commercial

(309) 782-0726.

HAND RECEIPT

This manual has a companion document with a TM number followed by -HR (which stands for Hand

Receipt). TM 9-2320-386-10-HR consists of preprinted hand receipts that list end item related equipment

(i.e., COEI, BII, and AAL) that must be accounted for. As an aid to property accountability, additional HR

manuals may be requisitioned through normal publication channels.

CORROSION PREVENTION AND CONTROL (CPC)

Corrosion Prevention and Control (CPC) of Army materiel is a continuing concern. It is important that

any corrosion problem(s) be reported so corrections and/or improvements can be made to prevent the

problem(s) in future items.

While corrosion is typically associated with rusting of metals, it can also include deterioration of other

materials, such as rubber and plastic. Unusual cracking, softening, swelling, or breaking of these materials

may be a corrosion problem.

If a corrosion problem is identified, it can be reported using Standard Form 368, Product Quality

Deficiency Report. Use of key words such as corrosion, rust, deterioration, or cracking will ensure that the

information is identified as a CPC problem.

The form should be submitted to the address specified in DA Pam 738-750.

0001 00-1

Back to Top