TM-9-2320-387-24-1 - Page 997 of 1205

TM

9-2320-387-24-i

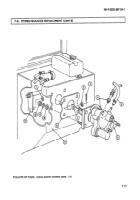

7-6. HYDRO-BOOSTER REPLACEMENT

This task covers:

a.

Removal

b.

Installation

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 11

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

MateriaWF’arts

Cotter pin (Appendix G, Item 36)

Spring washer (Appendix G, Item 452)

Four lockwashers (Appendix G, Item 217)

Manual References

TM 9-2320-387-24P

Equipment Condition

Master cylinder removed (para. 7-51.

Maintenance Level

Unit

Personnel Required

One mechanic

One assistant

1

a.

Removal

1

CAUTION

Cover or plug all open lines and connections immediately after

disconnection to prevent contamination. Remove all plugs prior to

connection.

NOTE

Have

drainage container ready to catch brake fluid.

1.

Mark and disconnect two high-pressure lines (4) and return line (5) from hydro-booster (6).

2.

Remove cotter pin (3) and washer (21, and disconnect pushrod (7) from brake pedal

bellcrank

(13).

Remove spring washer (11 from brake pedal bellcrank (131. Discard cotter pin (3) and spring washer (1).

3.

Remove four nuts (121,lockwashers (111, washers (lo), hydra-booster (61, and gasket (8) from cowl (9).

Discard lockwashers (11).

b. Installation

1.

Install gasket (8) and hydra-booster (6) on cowl (9) with four washers (lo), lockwashers (111, and

nuts (12). Do not tighten nuts (12).

2.

Install spring washer (1) on brake pedal bellcrank (13). Connect hydra-booster pushrod (7) to brake

pedal bellcrank (131 with washer (2) and cotter pin (3).

3.

Tighten nuts (121 to 21 lb-R (29 N-m).

4.

Connect two high-pressure lines (41 and return line (5) to hydro-booster (6).

7-16

Back to Top