TM-9-2320-387-24-2 - Page 288 of 1555

11-40. DRIVER’S FOOTWELL OUTER ARMOR MAINTENANCE

This task covers:

a.

Removal

c.

Installation

b.

Inspection

INITIAL SETUP:

Applicable Models

M1114

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

Materials/Parts

Four locknuts (Appendix G, Item 178)

Thirty-two locknuts (Appendix G, Item 169)

Sealing compound (Appendix C, Item 72.1)

Personnel Required

One mechanic

One assistant

Manual References

TM 9-2320-387-24P

Equipment Condition

• Headlight beam selector switch and bracket

removed (para. 4-59).

• Protective control box removed (para. 4-4).

Maintenance Level

Unit

TM 9-2320-387-24-2

11-82

Change 1

NOTE

If new driver’s footwell outer armor is installed, perform

para 11-36.1.

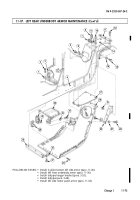

1.

Remove six capscrews (10) and spacer (6) from footwell armor (4) and A-beam armor (11).

2.

Remove twelve locknuts (9) and capscrews (13) from footwell armor (4) and outer cowl (2). Discard

locknuts (9).

3.

Remove fourteen locknuts (8) and capscrews (14) from footwell armor (4) and outer cowl (2). Discard

locknuts (8).

NOTE

Note location of screws and spacers for installation.

4.

Remove six locknuts (12), spacers (7), and capscrews (5) from footwell armor (4) and footwell (10.1).

Discard locknuts (12).

5.

Remove four locknuts (3), socket-head screws (1), and footwell armor (4) from outer cowl (2). Discard

locknuts (3).

Refer to para. 10-56 for plusnut inspection and replacement.

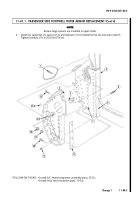

NOTE

Ensure large spacers are installed in upper holes.

1.

Install footwell armor (4) on footwell (10.1) with six capscrews (5), spacers (7), and locknuts (12).

Tighten locknuts (12) to 35 lb-ft (47 N

•

m).

2.

Secure footwell armor (4) to outer cowl (2) with four socket-head screws (1), locknuts (3), twelve

capscrews (13), locknuts (9), fourteen capscrews (14), and locknuts (8). Tighten locknuts (8) and (9) to

37 lb-ft (50 N

•

m). Tighten socket-head screws (1) to 10 lb-ft (13 N

•

m).

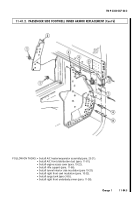

3.

Apply sealing compound to threads of six capscrews (10), and install spacer (6) and footwell armor (4)

on A-beam armor (11) with capscrews (10). Tighten capscrews (10) to 37 lb-ft (50 N

•

m).

c. Installation

b. Inspection

a. Removal

Back to Top