TM-9-2320-387-24-2 - Page 686 of 1555

Th49-2320-387-24-2

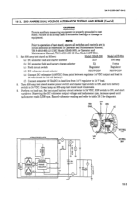

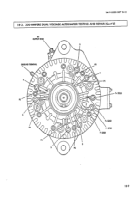

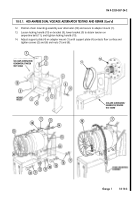

18-3. ILOO-AMPERE DUAL VOLTAGE ALTERNATOR TESTING AND REPAIR (Cont’d)

NOTE

l

When

tachometer reaches 3,000 rpm, green lamp should go off

indicating proper charging from alternator.

l

Normal voltage range is 26-30 VDC. High amperage is +lO percent

over the rated alternator output of 182 amps at 5,000 rpm.

10.

Perform no-load test. Increase alternator speed to 5,000 rpm; record results. Refer to table 18-1 for

diagnosis.

11.

Perform full-load test. Ensure all load switches are in ON position on 500-amp test stand, and

increase alternator speed to 5,000 rpm. Set load to 182 amps/mm, record results. Refer to table 18-2

for diagnosis.

Table 18-1. No-Load Test.

AhdPS(28v)

28V

VOLTS

14v

161-200

21-25

10.5-12.5

161-200

26-30

13-15

161-200

31-35

15.5-17.5

80-119

21-25

10.5-12.5

80-119

26-30

13-15

80-119

31-35

15.5-17.5

IPS

(28V)

161-200

28V

VOLTS

14v

!

DIAGNOSIS

21-25

10.5-12.5

161-200

26-30

13-15

161-200

31-35

15.5-17.5

80-119

21-25

10.5-12.5

80-119

26-30

13-15

80-119

31-35

15.5-17.5

C

DIAGNOSIS

Test bench battery is discharged (or

defective). Allow to charge (or replace).

Give time to stabilize while monitoring

VOLTS. If VOLTS rise above normal range

(26-30 volts), regulator and/or tube

assembly must be replaced. If

AMPS

fall,

charging systems OK

STOP TEST. Regulator and/or tube

assembly must be replaced. Refer

to

static

testing, task c.

Alternator and/or regulator must be

repaired or replaced. Refer to table 18-3.

Regulator OK Refer to table 18-2.

STOP TEST. Bench malfunction or wiring

error.

Table 18-2. FullLoad

Test.

‘Ikst bench battery is discharged (or

defective). Allow to charge (or replace).

Charging system OK

STOP TEST. Regulator and/or tube

assembly must be replaced. Refer to static

testing, task c.

Alternator and/or regulator must be

replaced. Refer to table 18-4.

Increase load.

STOP TEST. Test bench malfunction or

wiring error.

18-4

Back to Top