TM-9-2320-387-24-2 - Page 771 of 1555

21-5. DIFFERENTIAL REPLACEMENT (Cont'd)

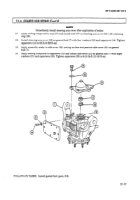

b. Installation

CAUTION

Apply a liberal amount of thread sealing compound to the tapped holes

of differential.

To allow adequate coating of threads, install capscrews

shortly after applying thread sealing compound. Failure to do this

could allow capscrews to loosen and cause damage to differential.

1.

For rear differentials, apply sealing compound to tapped holes in differential (11). Install two brake

caliper adapters (12) on differential (11) with four capscrews (10). Tighten capscrews (10) to

125-150 lb-ft (170-203 N

•

m).

2.

Raise differential (11) into place and connect vent line (13).

3.

Apply sealing compound in tapped holes in differential (11). Install differential (11) on two side

mounting brackets (1) with four washers (2) and capscrews (3).

4.

Install mounting bracket (4) on frame crossmember (20) with two washers (19), capscrews (18),

washers (19), and locknuts (21). Tighten locknuts (21) to 90 lb-ft (122 N

•

m).

NOTE

Rear differential is not equipped with washers as indicated in step 5.

5.

Apply sealing compound to capscrews (6). Install differential (11) on mounting bracket (4) with two

washers (5) and capscrews (6).

6.

Tighten capscrews (3) and (6) to 125-150 lb-ft (170-203 N

•

m).

7.

Connect propeller shaft (17) to pinion flange (14) with two straps (15) and four capscrews (16).

Tighten capscrews (16) to 13-18 lb-ft (18-24 N

•

m).

8.

Install two output flanges (9) on differential (11) with washer seals (7) and locknuts (8). Tighten

locknuts (8) to 165-195 lb-ft (224-264 N

•

m).

TM 9-2320-387-24-2

21-8

Change 1

Back to Top