TM-9-2330-247-14-P - Page 26 of 320

TM 9-2330-247-14&P

2-6.

GENERAL PMCS PROCEDURES (Con’t)

Electric Wires or Connectors. Inspect for cracked or broken insulation, bare wires, and loose or broken connectors.

Report loose connections and faulty wiring to Organizational Maintenance.

Hoses, Lines, and Fittings. Inspect for wear, damage, and leaks. Ensure that clamps and fittings are tight. Wet spots

show leaks, but a stain around a fitting or connector can also mean a leak. If a leak comes from a loose fitting or

connector, tighten it. If something is broken or worn out, either correct it or report it to Organizational Maintenance.

2-7.

SPECIFIC PMCS PROCEDURES

Always perform PMCS in the order listed. Once it becomes a habit, anything that is not right can be spotted in a minute.

Before performing PMCS, read all the checks required for the applicable interval and prepare all the tools needed.

Have several clean rags (Item 11, Appendix E) handy. Perform ALL inspections at the applicable interval.

If anything wrong is discovered through PMCS, perform the appropriate troubleshooting task in Chapter 3, Section Il. If

any component or system is not serviceable, or if a given service does not correct the problem, notify your supervisor.

2-8.

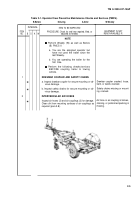

PMCS COLUMN DESCRIPTIONS

Item No. Provides a logical sequence for PMCS to be performed and is used as a source of item numbers for the “TM

ITEM NO” column when recording PMCS results on DA Form 2404.

Interval. Specifies the interval at which PMCS is to be performed.

Item To Be Inspected. Lists the system and common name of items that are to be inspected. Included in this column

are specific servicing, inspection, replacement, or adjustment procedures to be followed.

NOTE

The terms “ready/available” and “mission-capable” refer to the same status:

Equipment is on hand and is able to perform its combat missions (AR 700-138).

Equipment is Not/Ready Available If: Explains when the trailer is nonmission-capable.

2-9.

LEAKAGE Definitions

It is important to know how fluid leakage affects the status of the trailer. Following are types/classes of leakage an

operator must know to determine whether the trailer is mission-capable. Learn these leakage definitions. When in

doubt, notify your supervisor.

Leakage Definitions for Operator/Crew PMCS

Class I

Seepage of fluid (as indicated by wetness or discoloration) not

great enough to form drops.

Class II

Leakage of fluid great enough to form drops, but not great enough

to cause drops to drip from item being inspected.

Class III

Leakage of fluid great enough to form drops that fall from item being

inspected.

CAUTION

When operating with Class I or II leaks, continue to check fluid levels in addition to that

required by PMCS. Parts without fluid will stop working or may be damaged.

Equipment operation is allowed with minor (Class I or II) leakage. Fluid levels in an item/system affected with such

leakage must be checked more frequently than required in PMCS. When in doubt, notify your supervisor.

Report Class IlI leaks IMMEDIATELY to your supervisor.

2-4

Back to Top