TM-9-2330-331-14-P - Page 145 of 472

TM 9-2330-331-14&P

0022 00

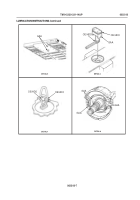

LUBRICATION INSTRUCTIONS-

Continued

6.

Clean fittings before lubrication using cleaning compound. Dry before lubricating.

7. The dotted leader lines in Figure 1, WP 0022 00-5, indicate lubrication is required on both sides of the

equipment.

8.

Re-lubricate after washing as necessary.

LUBRICATION TYPE/SPECIAL

LUBRICATION

INTERVAL

INSTRUCTIONS/MAINTENANCE

POINTS

LEVEL ()

ABS Sensor Body

When replaced or removed from

Spring Clip

GAA, When removed from spring clip,

clean off old grease and apply a new

light coat on sensor body.

Wipe off

excess. (O)

Automatic Slack Adjuster

Semiannually or every 6,000 miles

GAA, grease fittings. (O)

(9.656 km)

Detail 1

Semiannually or every 6,000 miles

OE/HDO-10, clevis pins, oil can

(9.656 km)

points. (O)

Stowage Box and

Semiannually or every 6,000 miles

OE/HDO-10, hinge/latch, oil can

Padlocks - Detail 3

(9,656 km)

points. (C)

Twist Locks (8)

Annually

GAA, grease fittings. (O)

Detail 6

OE/HDO-10, oil can points. (C)

Tiedown Rings

Semiannually or every 6,000 miles

Detail 7

(9,656 km)

OE/HDO-10, oil can points. (C)

Landing Gear Shoes,

Semiannually or every 6,000 miles

Swing Pins, and Crank

(9,656 km)

OE/HDO-10, oil can points. (C)

Handle - Detail 4

All Receptacle Pins

When disassembled/replaced

Dielectric Grease. Clean and Apply

and Connectors

a thin coat. (O)

0022 00-3

Back to Top