TM-9-2330-342-10 - Page 48 of 500

CORROSION PREVENTION AND CONTROL (CPC) - Continued

salts. An example is the rusting of iron. Corrosion damage in metals can be seen, depending

on the metal, as tarnishing, pitting, fogging, surface residue, and/or cracking.

Plastics, composites, and rubbers can also degrade. Degradation is caused by thermal

(heat), oxidation (oxygen), solvation (solvents), or photolytic (light, typically UV) processes.

The most common exposures are excessive heat or light. Damage from these processes

will appear as cracking, softening, swelling, and/or breaking.

SF Form 368, Product Quality Deficiency Report should be submitted to the address

specified in DA PAM 750-8, The Army Maintenance Management System (TAMMS) Users

Manual.

DESTRUCTION OF ARMY MATERIEL TO PREVENT ENEMY USE

Command decision, according to the tactical situation, will determine when the destruction

of the equipment will be accomplished. A destruction plan will be prepared by the using

organization unless one has been prepared by a higher authority. Refer to TM 750-244-6,

Procedures for Destruction of Tank Automotive Equipment to Prevent Enemy Use, for

general destruction procedures.

PREPARATION FOR STORAGE OR SHIPMENT

For detailed information on preparing the PLST M1076 A1 for storage or shipment refer to

WARRANTY INFORMATION

The PLST M1076 A1 is warranted for 12 months. The warranty starts on the date found in

block 23 of DA Form 2408-9, Equipment Control Record. Report all defects to your

supervisor, who will take appropriate action.

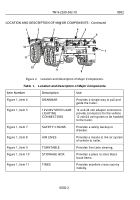

NOMENCLATURE CROSS-REFERENCE LIST

Table

1.

Nomenclature Cross-Reference List.

Common Name

Official Nomenclature

Gladhand

Quick disconnect air coupling

Service Brake Pedal

Brake pedal

Throttle Pedal

Throttle control

Towing Eye

Drawbar lunette

TM 9-2330-342-10

0001

0001-2

Back to Top