TM-9-2350-256-34 - Page 375 of 584

TM 9-2350-256-34

0068 00

INTERMEDIATE MAINTENANCE

RECOVERY VEHICLE, FULL TRACKED: MEDIUM, M88A1

NSN 2350-00-122-6826, EIC AQA

HOISTING

BOOM

ASSEMBLY

MAINTENANCE

DESCRIPTION, REMOVAL, DISASSEMBLY, INSPECTION, ASSEMBLY,

INSTALLATION, ADJUSTMENT, TESTING

INITIAL SETUP:

Test Equipment

Gage, pressure (item 9, WP 0086 00)

Tools and Special Tools

Adapter (item 1, WP 0086 00)

Puller (item 24, WP 0086 00)

Sling (item 30, WP 0086 00)

Sling assembly, lifting (item 31, WP 0086 00)

Tool kit, general mechanic’s (item 34, WP 0086 00)

Materials/Parts

Adhesive (item 2, WP 0085 00)

Clamps (2) (item 27, WP 0087 00)

Lockwashers (40) (item 160, WP 0087 00)

Lockwashers (8) (item 161, WP 0087 00)

Screws (40) (item 50, WP 0087 00)

Screws (4) (item 184, WP 0087 00)

Screws (4) (item 215, WP 0087 00)

Personnel Required

Mechanics (4)

DESCRIPTION

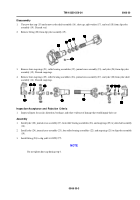

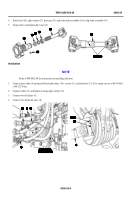

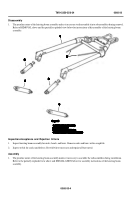

The hoisting boom assembly is a tubular A-frame that is pivot-mounted to the top of the vehicle. Hydraulic pressure raises or

lowers the boom by means of two boom-actuating cylinders that are activated by the boom control lever. The hoisting boom

assembly is capable of holding a 25-ton (22.68-metric ton) load. In operating position, the boom is supported by a stayline cable

secured to crank arms located at the rear of the hull. These crank arms are connected to hydraulically actuated stayline cylinders

that govern the reaching capacity of the hoisting boom assembly. A boom travel lock is provided for preventing movement of

the boom, particularly sideways, while traveling.

WARNING

Removal of hoisting boom assembly when both the main engine and APU engine are inoperable is a

safety hazard and may cause injury to personnel.

NOTE

LOAD TEST REQUIREMENT—Load testing of hoisting boom assembly is mandatory, prior

to use, under any of the following requirements: (1) When new. (2) Following any repairs,

disassembly and assembly, adjustments, or parts replacement, of hoisting boom assembly. (3)

When modifications are made that could affect the strength or lifting capabilities of the vehicle.

Load testing will be accomplished by support maintenance activities.

Refer to the TESTING section below for the detailed step-by-step procedure.

0068 00-1

Back to Top