TM-9-2350-273-BD - Page 56 of 288

TM 9-2350-273-BD

ENGINE

SECTION III. Engine Air Intake Systems

3-6. General.

Turbocharged engines use exhaust gases to drive the turbocharger to compress air and

force it into the cylinder under pressure. The engine air intake system is therefore

vacuum and pressure. Repairs to turbocharged air intake systems must be done with

materials that do not block the air flow. The materials must be securely attached to

prevent them from being sucked into the system up to the turbocharger inlet. The

repairs must seal so that the air pressure is maintained from the turbocharger outlet to

the intake manifold.

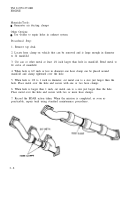

Figure 3-2. Engine Air Intake.

3-7. AIR CLEANER DAMAGED OR LEAKING

General Information

External location makes air cleaner vulnerable to damage. Dust ingestion will cause

extensive internal engine wear. Holes or cracks in the air cleaner housing or ducting

must be repaired or covered to keep dirt out of the air intake. Tape, auto body filler or

any other available material should be used to seal the air intake system. If the air

cleaner or ducting cannot be sealed they should be elimated using this procedure.

Limitations:

Degraded air intake efficiency

Personnel/Time Required:

1 soldier

30-60 minutes

3-5

Back to Top