TM-9-2350-273-BD - Page 59 of 288

TM 9-2350-273-BD

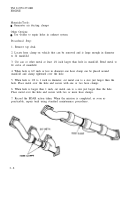

ENGINE

Materials/Tools:

Generator air ducting clamps

Other Options:

Use welder to repair holes in exhaust system.

Procedural Step:

1. Remove top deck.

2. Locate hose clamp on vehicle that can be removed and is large enough in diameter

to fit manifold.

3. Cut can or other metal at least 1/4 inch larger than hole in manifold. Bend metal to

fit curve of manifold.

4. When hole is 1/2 inch or less in diameter one hose clamp can be placed around

manifold and clamp tightened over the hole.

5. When hole is 1/2 to 1 inch in diameter, cut metal can to a size just larger than the

hole. Place metal over the hole and secure with one or two hose clamps.

6. When hole is larger than 1 inch, cut metal can to a size just larger than the hole.

Place metal over the hole and secure with two or more hose clamps.

7. Record the BDAR action taken. When the mission is completed, as soon as

practicable, repair tank using standard maintenance procedures.

3- 8

Back to Top