TM-9-2350-277-10 - Page 723 of 889

TM 9-2350-277-10

REMOVE/INSTALL T150 TRACK SHOE — Continued

0093 01

INSTALLATION

WARNING

Loss of track end connector can cause track throw and loss of vehicle control. Soldiers can be

killed or injured. Mark end connector bolts. Notify unit maintenance to torque bolts.

NOTE

Position track shoes at slight angle to install end connectors on both shoe pins. Proper

tightening of end connector bolts k eeps t hem from c o m in g loo se. H a ve un it ma in ten an c e

properly torque as soon as possible.

1.

Install new track shoe on track.

a.

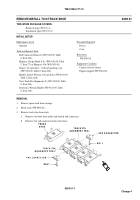

Install two track pin alignment tools over track shoe pins. Install two track end connectors on track shoes. Remove

track pin alignment tools before driving end connectors flush with pin ends.

b.

Drive end connectors flush with pin ends and install bolts on each end connector.

c.

Tighten bolts using wrench handle extension with socket.

2.

Mark track that was replaced so bolts can be torqued later.

3.

Join track WP 0092 01.

4.

Stow spare track shoe

5.

Notify maintenance to torque bolts.

6.

All n ew

,

installed t rack shoes r equire a check betw een 30 to 80 miles of operation. E ND CO NNECTO R B OLTS NEED

TO BE RETORQUED TO 400-430 LB-FT (543–583 N·M) TORQUE. Notify unit maintenance.

END OF TASK

0093 01-2

Change 4

Back to Top