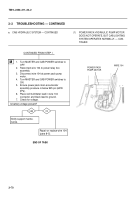

TM-9-2350-311-20-2 - Page 189 of 828

TM 9–2350–311–20–2

3–78

3–3

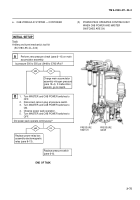

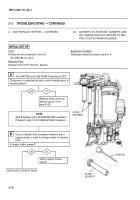

TROUBLESHOOTING — CONTINUED

f.

RAMMER HYDRAULIC SYSTEM

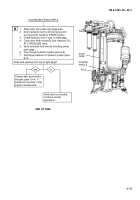

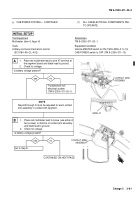

The rammer hydraulic system consists of the rammer, actuating valve, tray assembly, rammer cylinder, main release han-

dle, cylinder handle assembly, cylinder latch, and the blocking valve.

The rammer is used for loading and ramming the projectile into the tube. Hydraulic power from the power pack supplies the

pressure to the rammer cylinder which rams the projectile into position. Normal hydraulic pressure is between 925 to 1225

psi (6378 to 8446 kPa). The rammer actuating valve controls the inflow of hydraulic fluid for the ramming operation and

outflow of hydraulic fluid for the retraction of the rammer after use. The tray assembly holds the projectile in position for

ramming while the cylinder latch locks the rammer cylinder into position on the tray assembly. The rammer cylinder con-

tains a piston which rams the projectile into the chamber. The main release handle releases the locking mechanism so that

the rammer may be moved into RAM position, and also back into STOW position. The cylinder handle assembly provides a

hand hold for rotating the rammer cylinder into ramming position. The blocking valve prevents accidental ramming of ram-

mer in stowed position.

ACTUATING VALVE

BLOCKING VALVE

RAMMER

ASSEMBLY

MAIN

ACCUMULATOR

POWER

PACK

ASSEMBLY

POWER

RELAY

BOX

ASSEMBLY

SLIP RING ELECTRICAL

CONTACT HOLDER

OPERATING

PRESSURE

900 PSI

(6206 kPa)

DRAIN

RESERVOIR

PRESSURE

0 PSI (0 kPa)

PUMP PRES-

SURE

925–1225 PSI

(6378–8446 kPa)

GUNNER’S

SELECTOR

SWITCH BOX

ASSEMBLY

Back to Top