TM-9-2510-247-13-P - Page 489 of 522

TM 9-2510-247-13&P

0089 00

5.

TIGHTENING METAL FASTENERS - Continued

Table 7.

Torque Ranges

STATED RANGE

MOST EFFECTIVE RANGE

0-600 lb-ft (0-813.60 Nm)

150-450 lb-ft (203.40-610.20 Nm)

0-170 lb-ft (0-230.52 Nm)

44-131 lb-ft (59.67-177.64 Nm)

15-75 lb-ft (61.02-101.70 Nm)

30-60 lb-ft (40.68-81.36 Nm)

0089 00-5

6.

FASTENER SIZE AND THREAD PATTERN

Threaded fasteners are categorized according to diameter of the fastener shank. Thread styles

are divided into broad groups, the two most common being coarse (Unified Coarse-UNC) and fine (Unified

Fine-UNF0. These groups are defined by the number of threads per inch on the bolt shanks. In addition,

threads are categorized by thread class (Table 8), which is a measure of the degree between threads of bolt or

screw (external threads) and threads of the attaching nut or tapped hole (internal threads of the attaching nut or

tapped hole) (internal threads). The most common thread class for bolts and screws is Class 2.

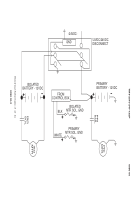

LENGTH

(BOLT SHANK)

THICKNESS

OR HEIGHT

OF HEAD

BODY LENGTH

NOMINAL DIAMETER

THREAD

RUNOUT

LENGTH

THREAD

LENGTH

GRIP

LENGTH

HEIGHT

OF NUT

LENGTH

(BOLT SHANK)

THICKNESS

OR HEIGHT

OF HEAD

BODY LENGTH

NOMINAL DIAMETER

THREAD

RUNOUT

LENGTH

THREAD

LENGTH

GRIP

LENGTH

HEIGHT

OF NUT

Back to Top