TM-9-2520-234-35 - Page 39 of 323

PAR 8-9

CHAPTER 2

DESCRIPTION AND OPERATION

Section I. DESCRIPTION AND OPERATION OF INPUT TRANSFER ASSEMBLY

8.

INPUT TRANSFER GEARING

a. Input Transfer Gearing

—

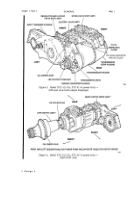

Components (fig. 373, fold-out 2)

(1) A cast aluminum transfe r

housing 126 encloses and supports the

transfer gearing. A cast aluminum flange

adapter 19 connects the vehicle engine

flywheel housing to the transfer gear hous-

ing. The rear of transfer housing 126 is

bolted to the torque converter housing.

(2) A spline d

engine coupling

shaft 23 delivers engine torque to the gear

train. The gear train consists of a 68-tooth

drive gear 25, a 52-tooth idler cluster gear

34, a 34- and 54-tooth cluster gear 41, and

a 66-tooth converter pump cover drive

gear 67. These gears have 6-pitch teeth.

The drive gear is supported in housing 126

and adapter 19 by single-row ball bearings

24 and 27. Idler gear 34 is supported on a

spindle 5 by a double-row ball bearing 35.

Idler cluster gear 41 is supported o n

spindle 153 by two straight roller bearings

38 and 40. Converter pumpcover drive

gear 67 is bolted to converter cove r

assembly 68.

Idler gear 34 includes a

36-tooth oil pump drive gear .

The

29-tooth oil pump driven gear 109 i s

supported by a single-row ball bearing 110.

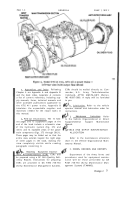

b.

to the

splined

Operation of Input Transfer

Gearing (fig. 20)

(1) Engine rotation is transmitted

68-tooth transfer drive gear by a

coupling shaft.

The drive gear

drives the 52-tooth gear which, in turn,

meshes with the 34-tooth gear on the

cluster idler gear. The 54-tooth gear on

the cluster idler gear drives the 66-tooth

converter pump cover drive gear.

(2) The converter cover is thus

driven in a direction opposite to that of

the engine and at a speed 1.64 times

greater than engine speed. Rotation of

the converter is clockwise, viewed from

the left side of the power train. The oil

pump driven gear is driven counterclock-

wise at 1.62 times engine speed.

9.

TORQUE CONVERTER AND

LOCKUP CLUTCH

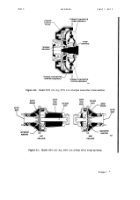

a. Torque Converter Components

—

(fig. 373, fold-out 2)

(1) The torque converter consists

mainly of three cast aluminum elements:

pump assembly 82, stator assembly 94 and

turbine assembly 79. These, and related

minor components, are enclosed and sup-

ported by the input transfer housing 126

and converter housing 31 (fig. 374, fold-

out 3).

(2) Pump assembly 82 (fig. 373,

fold-out 2) has radial vanes cast into one

side surface. It is machined at the center

and bolted to a steel hub 88. The hub is

supported by a single-row ball bearing 91

which, in turn, is mounted on a stationary

ground sleeve 26 (fig. 374, fold-out 3).

The ground sleeve is rigidly mounted in

converter housing 31. The outside diam-

eter of pump assembly 82 (fig. 373, fold-

out 2) is bolted to converter cover assem-

bly 68.

(3)

The

stator

assembly

is

a

vaned reaction member. It includes stator

94, freewheel race 101, freewheel bearings

97, springs 98, cam 99 and various minor

components. This assembly mounts on the

splined outside diameter of the ground

sleeve 26 (fig. 374, fold-out 3). The stator

can freewheel in the direction of conver-

ter rotation but will lock up if an attempt

is made to rotate it in the opposite direc-

tion.

(4) Turbine assembly 79 (fig. 373,

fold-out 2) is a vaned casting similar to

pump assembly 82. It is riveted to a steel

hub which has internal splines which en-

gage turbine shaft 2 (fig. 375, fold-out 4).

A single-row ball bearing 73 (fig. 373,

11

Back to Top